化学学报 ›› 2022, Vol. 80 ›› Issue (3): 317-326.DOI: 10.6023/A21100451 上一篇 下一篇

研究论文

投稿日期:2021-10-09

发布日期:2022-02-08

通讯作者:

李箭

基金资助:

Jun Luo, Lichao Jia, Dong Yan, Jian Li( )

)

Received:2021-10-09

Published:2022-02-08

Contact:

Jian Li

Supported by:文章分享

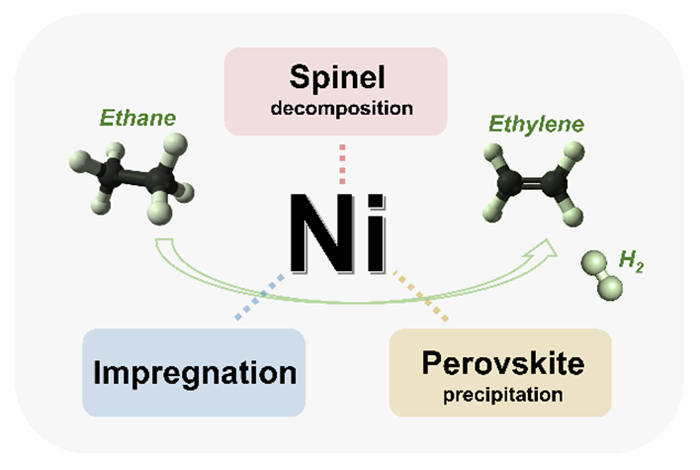

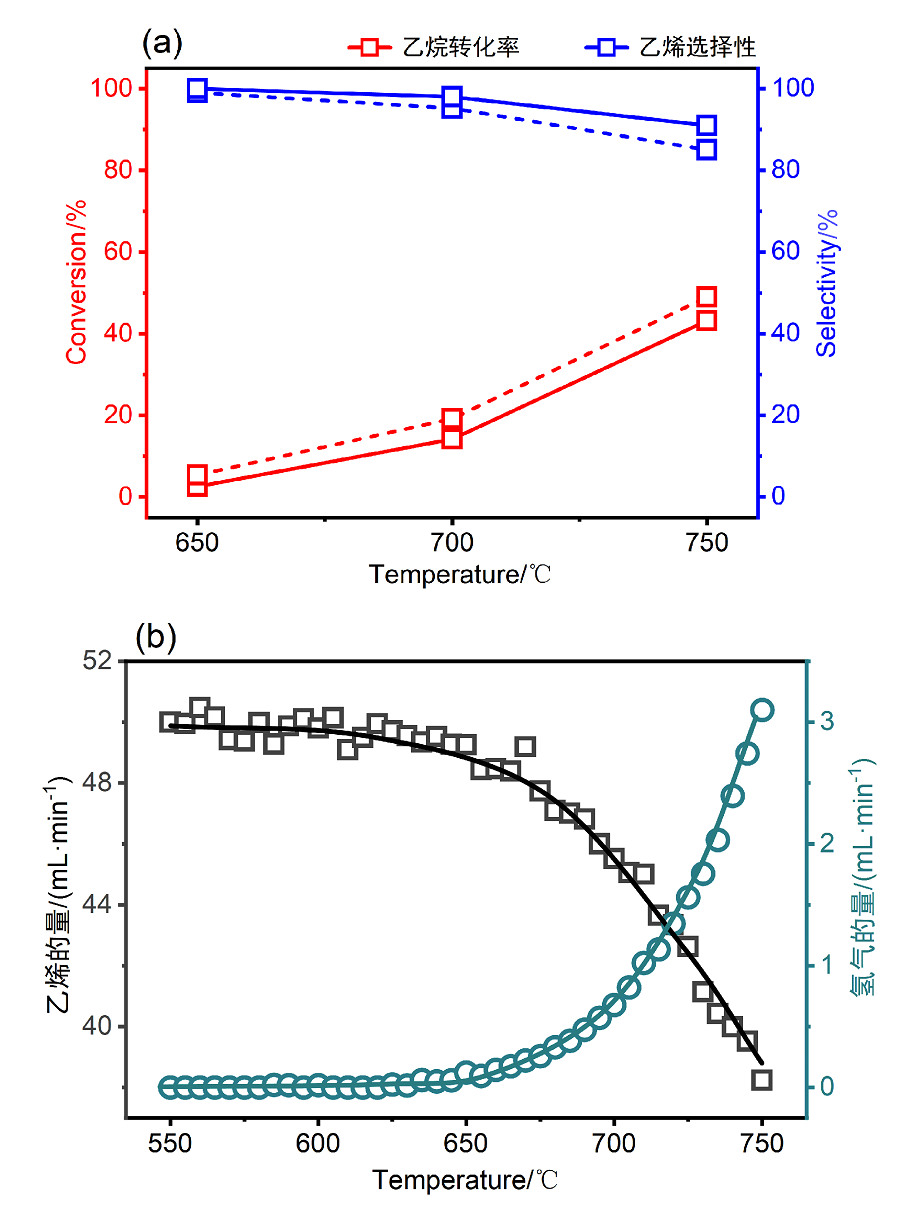

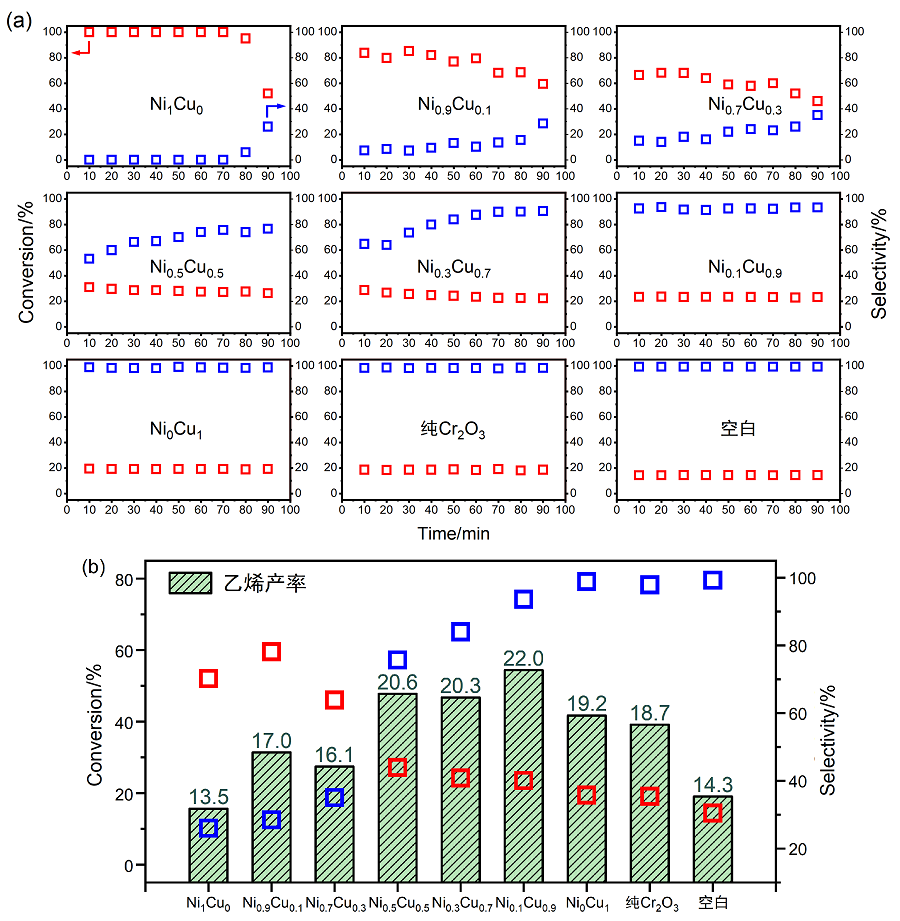

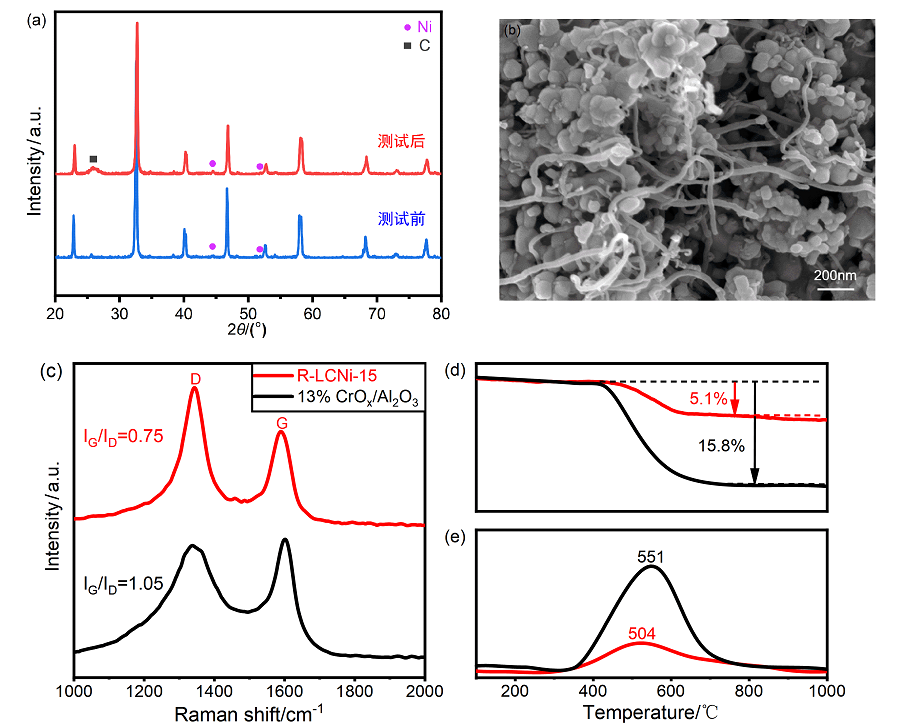

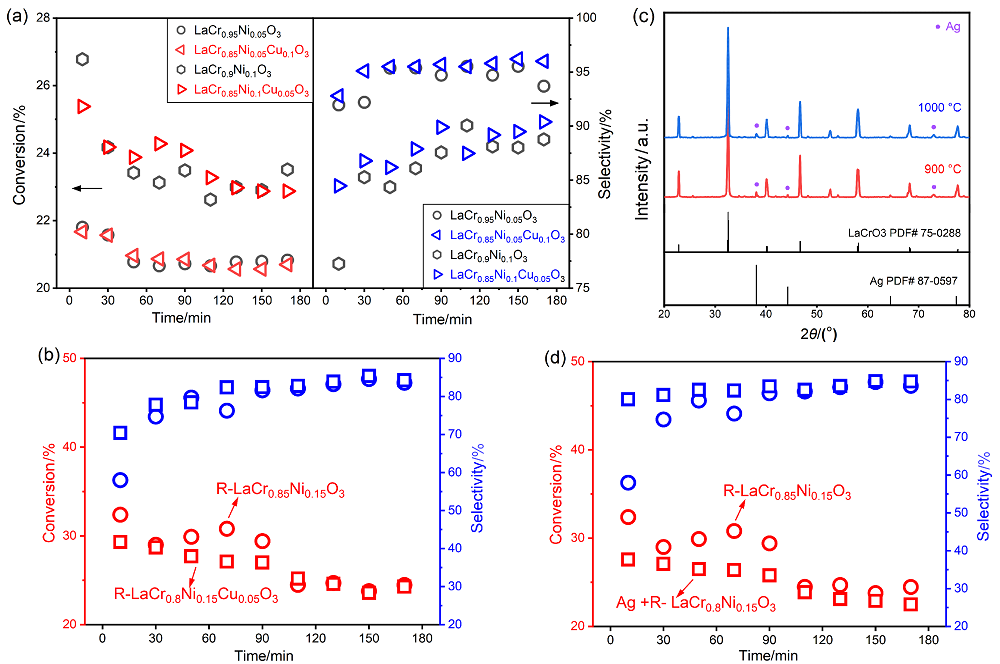

过渡金属Ni是地球上储量丰富的金属元素, 在加氢脱硫、重整制氢等催化领域应用非常广泛, 但是关于Ni基催化剂在烷烃脱氢方面的研究较少; 因此, 本工作采用不同的方法, 制备了三种结构的Ni基负载催化剂, 即尖晶石分解型、浸渍型和钙钛矿析出型, 并在700 ℃、C2H6-N2气氛中和50 mL•min-1气体流速下, 探索了它们的乙烷脱氢性能. 结果表明: 尖晶石分解型催化剂Ni1-xCuxCr2O4还原后在Cr2O3表面形成Ni-Cu合金颗粒, 能有效钝化Ni的C—C键断裂活性, 提高乙烯的选择性. Ni含量过高时, Ni不能有效地分散而形成大的金属团簇, 造成乙烷过度裂解, 乙烯选择性较低. 浸渍负载型催化剂NixMy/Al2O3 (M为Cu或Ag) 比表面积大, 表面活性位点分散, 但活性金属与载体结合力弱, 在高温下不稳定; Cu或Ag与Ni形成合金, 可有效提高乙烯选择性, Ag较Cu的效果更佳. 钙钛矿析出型催化剂LaCr1-xNixO3(LCNi-100x)在还原气氛中析出均匀细小的Ni颗粒, 其与基体结合力强, 抗积碳性能和稳定性较高; 含15% Ni的LCNi-15还原后(R-LCNi-15)表现出最好的催化性能, 乙烯产率最高(24%), 同时具有较好的抗积碳性能和稳定性以及氧化再生性.

罗俊, 贾礼超, 颜冬, 李箭. Ni基乙烷脱氢催化剂的性能及其改进[J]. 化学学报, 2022, 80(3): 317-326.

Jun Luo, Lichao Jia, Dong Yan, Jian Li. Performance and Improvement of Ni-based Catalysts for Ethane Dehydrogenation[J]. Acta Chimica Sinica, 2022, 80(3): 317-326.

| 催化剂 | 乙烷转化率/% | 乙烯选择性/% | 碳平衡/% |

|---|---|---|---|

| R-LCNi-15 | 29.4 | 83.2 | 94.3 |

| 13% CrOx/Al2O3 | 20.4 | 87.6 | 90.4 |

| 催化剂 | 乙烷转化率/% | 乙烯选择性/% | 碳平衡/% |

|---|---|---|---|

| R-LCNi-15 | 29.4 | 83.2 | 94.3 |

| 13% CrOx/Al2O3 | 20.4 | 87.6 | 90.4 |

| [1] |

Zhang, Y.; Wang, L.; Li, M.; Feng, W. Z.; Zhang, Y. Contemp. Chem. Ind. 2018, 47, 113. (in Chinese)

|

|

张阳, 王蕾, 李明, 冯伟忠, 张允, 当代化工, 2018, 47, 113.)

|

|

| [2] |

Zimmermann, H.; Walzl, R. Ullmann's Encyclopedia of Industrial Chemistry, Wiley, Weinheim, 2009, pp. 465-526.

|

| [3] |

Wang, F.; Luo, M.; Xiao, W. D.; Chen, X. W.; Long, Y. C. Petrkchem. Technol. 2011, 40, 12. (in Chinese)

|

|

(王飞, 罗漫, 肖文德, 程晓维, 龙英才, 石油化工, 2011, 40, 12.)

|

|

| [4] |

Research and Design Institute of Shengli Petrochemical Plant, Cracking of Petroleum Hydrocarbons to Ethylene, Fuel Chemical, Fuel Chemical Industry Press, Beijing, 1974. (in Chinese)

|

|

(胜利石油化工总厂科研设计所, 石油烃类裂解制乙烯, 燃料化学工业出版社, 北京, 1974.)

|

|

| [5] |

Liu, H. T.; Li, H. Q.; Yang, W. J.; Wang, X. R.; Zhang, Y. Acta Chim. Sinica 2009, 67, 1749. (in Chinese)

|

|

(柳海涛, 李会泉, 杨玮娇, 王兴瑞, 张懿, 化学学报, 2009, 67, 1749.)

|

|

| [6] |

Iglesias-Juez, A.; Beale, A. M.; Maaijen, K.; Weng, T. C.; Glatzel, P.; Weckhuysen, B. M. J. Catal. 2010, 276, 268.

doi: 10.1016/j.jcat.2010.09.018 |

| [7] |

Lieske, H.; Sárkány, A.; Völter, J. Appl. Catal. 1987, 30, 69.

doi: 10.1016/S0166-9834(00)81012-X |

| [8] |

Pham, H. N.; Sattler, J. J.; Weckhuysen, B. M.; Datye, A. K. ACS Catal. 2016, 6, 2257.

doi: 10.1021/acscatal.5b02917 |

| [9] |

Childers, D. J.; Schweitzer, N. M.; Shahari, S. M. K.; Rioux, R. M.; Miller, J. T.; Meyer, R. J. J. Catal. 2014, 318, 75.

doi: 10.1016/j.jcat.2014.07.016 |

| [10] |

Kitchin, J. R.; Norskov, J. K.; Barteau, M. A.; Chen, J. G. J. Chem. Phys. 2004, 120, 10240.

pmid: 15268048 |

| [11] |

Virnovskaia, A.; Morandi, S.; Rytter, E.; Ghiotti, G.; Olsbye, U. J. Phys. Chem. C 2007, 111, 14732.

doi: 10.1021/jp074686u |

| [12] |

Xia, Z. J.; Lu, H. F.; Liu, H. Y.; Zhang, Z. K.; Chen, Y. F. Catal. Commun. 2017, 90, 39.

doi: 10.1016/j.catcom.2016.10.036 |

| [13] |

Yao, Y.; Goodman, D. W. RSC Adv. 2015, 5, 43547.

doi: 10.1039/C5RA07433A |

| [14] |

He, D.; Zhang, Y.; Yang, S.; Mei, Y.; Luo, Y. ChemCatChem 2018, 10, 5434.

doi: 10.1002/cctc.v10.23 |

| [15] |

Liu, Y.; Zhao, J.; Feng, J.; He, Y.; Du, Y.; Li, D. J. Catal. 2018, 359, 251.

doi: 10.1016/j.jcat.2018.01.009 |

| [16] |

Khromova, S. A.; Smirnov, A. A.; Bulavchenko, O. A.; Saraev, A. A.; Kaichev, V. V.; Reshetnikov, S. I.; Yakovlev, V. A. Appl. Catal. A-Gen. 2014, 470, 261.

doi: 10.1016/j.apcata.2013.10.046 |

| [17] |

Vang, R. T.; Honkala, K.; Dahl, S.; Vestergaard, E. K.; Schnadt, J.; Laegsgaard, E.; Clausen, B. S.; Norskov, J. K.; Besenbacher, F. Nat. Mater. 2005, 4, 160.

doi: 10.1038/nmat1311 |

| [18] |

Rovik, A. K.; Klitgaard, S. K.; Dahl, S.; Christensen, C. H.; Chorkendorff, I. Appl. Catal., A 2009, 358, 269.

doi: 10.1016/j.apcata.2009.02.020 |

| [19] |

Oh, T. S.; Rahani, E. K.; Neagu, D.; Irvine, J. T.; Shenoy, V. B.; Gorte, R. J.; Vohs, J. M. J. Phys. Chem. Lett. 2015, 6, 5106.

doi: 10.1021/acs.jpclett.5b02292 |

| [20] |

Kwon, O.; Sengodan, S.; Kim, K.; Kim, G.; Jeong, H. Y.; Shin, J.; Ju, Y. W.; Han, J. W.; Kim, G. Nat. Commun. 2017, 8, 15967.

doi: 10.1038/ncomms15967 |

| [21] |

Neagu, D.; Oh, T. S.; Miller, D. N.; Menard, H.; Bukhari, S. M.; Gamble, S. R.; Gorte, R. J.; Vohs, J. M.; Irvine, J. T. S. Nat. Commun. 2015, 6, 8120.

doi: 10.1038/ncomms9120 |

| [22] |

Sun, X.; Chen, H. J.; Yin, Y. M.; Curnan, M. T.; Han, J. W.; Chen, Y.; Ma, Z. F. Small 2021, 17, 2005383.

doi: 10.1002/smll.v17.10 |

| [23] |

Wei, T.; Jia, L. C.; Zheng, H. Y.; Chi, B.; Pu, J.; Li, J. Appl. Catal., A 2018, 564, 199.

doi: 10.1016/j.apcata.2018.07.031 |

| [24] |

Abild-Pedersen, F.; Norskov, J. K.; Rostrup-Nielsen, J. R.; Sehested, J.; Helveg, S. Phys. Rev. B 2006, 73, 115419.

doi: 10.1103/PhysRevB.73.115419 |

| [25] |

Wei, T.; Jia, L. C.; Luo, J. L.; Chi, B.; Pu, J.; Li, J. Appl. Surf. Sci. 2019, 506, 144699.

doi: 10.1016/j.apsusc.2019.144699 |

| [1] | 贾洋刚, 陈诗洁, 邵霞, 程婕, 林娜, 方道来, 冒爱琴, 李灿华. 高性能无钴化钙钛矿型高熵氧化物负极材料的制备及储锂性能研究[J]. 化学学报, 2023, 81(5): 486-495. |

| [2] | 朱凤巧, 王文贵, 瞿旭东, 王守锋. 硫肽类抗生素化学半合成修饰研究进展[J]. 化学学报, 2022, 80(10): 1448-1462. |

| [3] | 肖莹霞, 柳忠全. 富电子杂环芳烃与酮酯的自由基脱氢偶联反应[J]. 化学学报, 2019, 77(9): 874-878. |

| [4] | 王永胜, 赵云鹭, 赵珍珍, 兰小林, 徐金霞徐伟祥, 段正康. 氮掺杂碳包覆Cu-ZrO2催化剂的制备及其催化脱氢性能研究[J]. 化学学报, 2019, 77(7): 661-668. |

| [5] | 付雯雯, 李严, 梁长海. 乙醇在Co(111)表面脱氢反应机理的第一性原理研究[J]. 化学学报, 2019, 77(6): 559-568. |

| [6] | 关弘浩, 陈磊, 刘磊. 饱和开链醚的氧化碳氢炔基化研究[J]. 化学学报, 2018, 76(6): 440-444. |

| [7] | 邵天举, 江智勇. 可见光催化有氧脱氢合成2,3-二氢-4-吡啶酮与4-喹诺酮[J]. 化学学报, 2017, 75(1): 70-73. |

| [8] | 马玉勇, 李微, 俞飚. 钯促进的碳氢键活化在齐墩果酸D和E环脱氢烯化中的应用研究[J]. 化学学报, 2013, 71(04): 541-548. |

| [9] | 齐随涛, 黄俊, 陈昊, 高子丰, 伊春海, 杨伯伦. 有机氢化物可逆储氢循环中脱氢催化剂的研究进展[J]. 化学学报, 2012, 70(24): 2467-2474. |

| [10] | 练荣伟, 田晶, 高鹏, 王希越, 费旭, 王一, 许国旺. 代谢指纹分析筛选调节金橙黄微小杆菌ATCC49676乳酸产量的代谢物[J]. 化学学报, 2012, 70(24): 2513-2517. |

| [11] | 陈战国, 王丹, 李亚男, 王英杰, 胡均利, 夏伟. 功能化烯胺的合成(I): 混合溶剂中硫脲催化α,β-邻位氨基溴转变成α,β-脱氢氨[J]. 化学学报, 2012, 70(21): 2236-2245. |

| [12] | 刘龑, 王正, 丁奎岭. DpenPhos/Rh(I)催化的β-脱氢氨基酸酯的不对称氢化反应[J]. 化学学报, 2012, 70(13): 1464-1470. |

| [13] | 俞超, 秦枫, 熊德胜, 侯磊, 沈伟, 徐华龙. Ga2O3/HZSM-5催化剂在乙烷脱氢反应中的积碳行为和MgO的修饰作用[J]. 化学学报, 2011, 69(20): 2413-2419. |

| [14] | 刘素琴,陈东洋,黄可龙,仲晓铃. MgNi-x% TiNi0.5Mn0.5 (x=10, 30, 50)贮氢合金的制备与电化学性能[J]. 化学学报, 2009, 67(6): 513-518. |

| [15] | 柳海涛,李会泉,杨玮娇,王兴瑞,张懿. Cr/MSU-1催化剂中Cr含量对CO2氧化丙烷脱氢反应催化性能的影响[J]. 化学学报, 2009, 67(15): 1749-1753. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||