化学学报 ›› 2023, Vol. 81 ›› Issue (4): 406-419.DOI: 10.6023/A22120513 上一篇 下一篇

综述

宁聪聪a, 杨倩b,*( ), 毛阿敏a, 唐梓嘉a, 金燕a, 胡宝山a,*(

), 毛阿敏a, 唐梓嘉a, 金燕a, 胡宝山a,*( )

)

投稿日期:2022-12-28

发布日期:2023-03-16

作者简介: |

宁聪聪, 重庆大学2020级在读硕士生. 2020年毕业于江南大学, 获得学士学位. 主要从事石墨烯纳米带的生长及性质研究, 发表SCI论文1篇. |

|

杨倩, 博士, 助理研究员, 硕士生导师. 2013年毕业于重庆大学获学士学位, 2018年毕业于重庆大学获博士学位. 2018年~2020年在北京大学化学与分子工程学院从事博士后研究, 2021年加入重庆科技学院工作. 研究方向为二维材料的制备及其应用. 主持国家自然科学基金1项, 发表SCI论文10余篇. |

|

毛阿敏, 重庆大学2020级在读硕士生. 2020年毕业于重庆大学, 获得学士学位. 主要从事石墨烯的可控制备及性质应用研究. |

|

唐梓嘉, 重庆大学2021级在读硕士生. 2021年毕业于武汉理工大学, 获得学士学位. 主要从事石墨烯条带的可控制备及其性质研究. |

|

金燕, 重庆大学化学化工学院实验师, 主要从事石墨烯及其复合材料的控制制备及其应用研究, 发表SCI论文10余篇. |

|

胡宝山, 重庆大学化学化工学院副院长, 副教授, 重庆市引进高层次人才. 主要研究方向为碳纳米材料控制制备、功能化及其应用. 主持多个国家级和省部级项目, 发表SCI论文50余篇. |

基金资助:

Congcong Ninga, Qian Yangb,*( ), Amin Maoa, Zijia Tanga, Yan Jina, Baoshan Hua,*(

), Amin Maoa, Zijia Tanga, Yan Jina, Baoshan Hua,*( )

)

Received:2022-12-28

Published:2023-03-16

Contact:

* E-mail: Supported by:文章分享

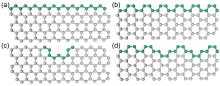

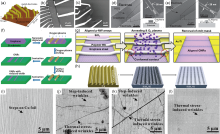

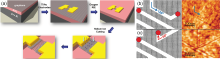

石墨烯纳米带是宽度为纳米尺度的石墨烯条带, 根据其边缘构型的不同可以分为锯齿型石墨烯纳米带和扶手型石墨烯纳米带. 纳米尺度导致的量子限域效应和边缘构型引起的边缘效应能够调节石墨烯纳米带的电子结构, 打开石墨烯的带隙. 而且, 石墨烯纳米带具有极大的长宽比和极高比例的边缘原子, 为通过结构裁剪实现功能定制提供了无限可能. 这些几何和电子结构特性使得石墨烯纳米带在电子器件等诸多领域比石墨烯具有更大的应用潜力, 因此, 石墨烯纳米带的相关研究一直是纳米材料领域的热点. 基于此, 本综述首先介绍了石墨烯纳米带的结构和性质, 全面介绍了石墨烯纳米带的制备方法, 相应的制备方法可以分为两部分: (1)自上而下法: 通过等离子体、离子束、扫描隧道显微镜和金属纳米颗粒对石墨烯和碳纳米管进行刻蚀和切割, 制备石墨烯纳米带. 该方法面临最大挑战在于如何提高刻蚀和切割精度. (2)自下而上法: 利用含碳前驱体, 如有机化合物、碳氢化合物气体以及碳化硅等, 制备石墨烯纳米带. 该方法利于实现原子精度的结构控制, 尤其是化学气相沉积法有望实现低成本、规模化制备. 最后展望石墨烯纳米带研究的挑战和前景. 我们相信, 随着材料和技术的创新发展, 石墨烯纳米带必将成为一种具有巨大应用潜力的新型功能材料.

宁聪聪, 杨倩, 毛阿敏, 唐梓嘉, 金燕, 胡宝山. 石墨烯纳米带的可控制备研究进展[J]. 化学学报, 2023, 81(4): 406-419.

Congcong Ning, Qian Yang, Amin Mao, Zijia Tang, Yan Jin, Baoshan Hu. Research Progress in Controllable Preparation of Graphene Nanoribbons[J]. Acta Chimica Sinica, 2023, 81(4): 406-419.

| 制备方法 | 优点 | 缺点 | |

|---|---|---|---|

| 切割石墨烯 | 掩模刻蚀法[ | 大面积、可控图案化制备 | 加工精度低、边缘结构不规则、掩模去除困难 |

| 无掩模刻蚀法[ | 加工精度高、边缘结构可控、制备质量高 | 生产成本高、生产规模小 | |

| 切割碳纳米管 | 氧化反应切割法[ | 原料成本低 | 提纯工艺复杂 |

| 纳米粒子切割法[ | 条带缺陷少、边缘平直且洁净 | 切割方向难控制、边缘结构不规则 | |

| 等离子体切割法[ | 条带宽度低至数十纳米 | 边缘结构不规则 | |

| 有机合成法 | 真空表面合成法[ | 条带宽度低至数纳米 | 条带较短、对设备要求高、成本高 |

| 常压表面合成法[ | 效率高、条带宽度窄 | 生产规模小 | |

| 溶液合成法[ | 反应条件温和、无需贵金属催化剂 | 提纯复杂、产率低、制备过程复杂 | |

| SiC外延生长法[ | — | 无需转移、条带质量高 | 生产规模小 |

| CVD生长法 | 选区直接生长法[ | 条带质量高、大面积可控制备 | 条带长宽比较小 |

| 模板生长法[ | 条带较长、质量高 | 条带长宽比较小 | |

| 限域生长法[ | 条带较长、质量高、可控图案化制备 | 条带宽度控制困难 | |

| 制备方法 | 优点 | 缺点 | |

|---|---|---|---|

| 切割石墨烯 | 掩模刻蚀法[ | 大面积、可控图案化制备 | 加工精度低、边缘结构不规则、掩模去除困难 |

| 无掩模刻蚀法[ | 加工精度高、边缘结构可控、制备质量高 | 生产成本高、生产规模小 | |

| 切割碳纳米管 | 氧化反应切割法[ | 原料成本低 | 提纯工艺复杂 |

| 纳米粒子切割法[ | 条带缺陷少、边缘平直且洁净 | 切割方向难控制、边缘结构不规则 | |

| 等离子体切割法[ | 条带宽度低至数十纳米 | 边缘结构不规则 | |

| 有机合成法 | 真空表面合成法[ | 条带宽度低至数纳米 | 条带较短、对设备要求高、成本高 |

| 常压表面合成法[ | 效率高、条带宽度窄 | 生产规模小 | |

| 溶液合成法[ | 反应条件温和、无需贵金属催化剂 | 提纯复杂、产率低、制备过程复杂 | |

| SiC外延生长法[ | — | 无需转移、条带质量高 | 生产规模小 |

| CVD生长法 | 选区直接生长法[ | 条带质量高、大面积可控制备 | 条带长宽比较小 |

| 模板生长法[ | 条带较长、质量高 | 条带长宽比较小 | |

| 限域生长法[ | 条带较长、质量高、可控图案化制备 | 条带宽度控制困难 | |

| [1] |

Balandin, A. A. Nat. Mater. 2011, 10, 569.

doi: 10.1038/nmat3064 |

| [2] |

Chen, X. D.; Chen, Z. L.; Sun, J. Y.; Zhang, Y. F.; Liu, Z. F. Acta Phys.-Chim. Sin. 2016, 32, 14. (in Chinese)

doi: 10.3866/PKU.WHXB201511133 |

|

(陈旭东, 陈召龙, 孙靖宇, 张艳锋, 刘忠范, 物理化学学报, 2016, 32, 14.)

|

|

| [3] |

Lee, C.; Wei, X.; Kysar, J. W.; Hone, J. Science 2008, 321, 385.

doi: 10.1126/science.1157996 |

| [4] |

Nair, R. R.; Blake, P.; Grigorenko, A. N.; Novoselov, K. S.; Booth, T. J.; Stauber, T.; Peres, N. M. R.; Geim, A. K. Science 2008, 320, 1308.

doi: 10.1126/science.1156965 pmid: 18388259 |

| [5] |

Cheng, Y.; Wang, K.; Qi, Y.; Liu, Z. F. Acta Phys.-Chim. Sin. 2022, 38, 2006046. (in Chinese)

|

|

(程熠, 王坤, 亓月, 刘忠范, 物理化学学报, 2022, 38, 2006046.)

|

|

| [6] |

Jian, M. Q.; Zhang, Y. Y.; Liu, Z. F. Acta Phys.-Chim. Sin. 2022, 38, 2007093. (in Chinese)

|

|

(蹇木强, 张莹莹, 刘忠范, 物理化学学报, 2022, 38, 2007093.)

|

|

| [7] |

Novoselov, K. S.; Geim, A. K.; Morozov, S. V.; Jiang, D.; Zhang, Y.; Dubonos, S. V.; Grigorieva, L. V.; Firsov, A. A. Science 2004, 306, 666.

doi: 10.1126/science.1102896 pmid: 15499015 |

| [8] |

Ghaffarkhah, A.; Hosseini, E.; Kamkar, M.; Sehat, A. A.; Dordanihaghighi, S.; Allahbakhsh, A.; van der Kuur, C.; Arjmand, M. Small 2022, 18, 2102683.

doi: 10.1002/smll.v18.2 |

| [9] |

Li, J. Z.; Chen, M. G.; Samad, A.; Dong, H. C.; Ray, A.; Zhang, J. W.; Jiang, X. C.; Schwingenschlogl, U.; Domke, J.; Chen, C. L.; Han, Y.; Fritz, T.; Ruoff, R. S.; Tian, B.; Zhang, X. X. Nat. Mater. 2022, 21, 740.

doi: 10.1038/s41563-021-01174-1 |

| [10] |

Wang, Z. Y.; Li, J. F.; Liu, S. Y.; Shao, G. F.; Zhao, X. J. Nanoscale 2022, 14, 16944.

doi: 10.1039/D2NR04378E |

| [11] |

Wang, F.; Wang, B. Y.; You, W.; Chen, G.; You, Y. Z. Nano Res. 2022, 15, 9223.

doi: 10.1007/s12274-022-4599-5 |

| [12] |

Lawrence, J.; Berdonces-Layunta, A.; Edalatmanesh, S.; Castro- Esteban, J.; Wang, T.; Jimenez-Martin, A.; de la Torre, B.; Castrillo- Bodero, R.; Angulo-Portugal, P.; Mohammed, M. S. G.; Matej, A.; Vilas-Varala, M.; Schiller, F.; Corso, M.; Jelinek, P.; Pena, D.; de Oteyza, D. G. Nat. Chem. 2022, 14, 1451.

doi: 10.1038/s41557-022-01042-8 |

| [13] |

Chen, W. Y.; Ge, C.; Li, J. T.; Beckham, J. L.; Yuan, Z.; Wyss, K. M.; Advincula, P. A.; Eddy, L.; Kittrell, C.; Chen, J. H.; Luong, D. X.; Carter, R. A.; Tour, J. M. ACS Nano 2022, 16, 6646.

doi: 10.1021/acsnano.2c01136 |

| [14] |

Sahalianov, I. Y.; Radchenko, T. M.; Tatarenko, V. A.; Cuniberti, G.; Prylutskyy, Y. I. J. Appl. Phys. 2019, 126, 054302.

doi: 10.1063/1.5095600 |

| [15] |

Torres-Rojas, R. M.; Contreras-Solorio, D. A.; Hernández, L.; Enciso, A. Solid State Commun. 2022, 341, 114553.

doi: 10.1016/j.ssc.2021.114553 |

| [16] |

Liu, Y.; Coppens, M. O. Adv. Funct. Mater. 2022, 32, 2200199.

doi: 10.1002/adfm.v32.31 |

| [17] |

Nandee, R.; Chowdhury, M. A.; Shahid, A.; Hossain, N.; Rana, M. Results in Engineering 2022, 15, 100474.

doi: 10.1016/j.rineng.2022.100474 |

| [18] |

Nakada, K.; Fujita, M. Phys. Rev. B 1996, 54, 17954.

pmid: 9985930 |

| [19] |

Zheng, X. Q.; Feng, M.; Zhan, H. B. Prog. Chem. 2012, 24, 2320. (in Chinese)

|

|

(郑小青, 冯苗, 詹红兵, 化学进展, 2012, 24, 2320.)

|

|

| [20] |

Son, Y. W.; Cohen, M. L.; Louie, S. G. Phys. Rev. Lett. 2006, 97, 216803.

doi: 10.1103/PhysRevLett.97.216803 |

| [21] |

Han, M. Y.; Ozyilmaz, B.; Zhang, Y.; Kim, P. Phys. Rev. Lett. 2007, 98, 206805.

doi: 10.1103/PhysRevLett.98.206805 |

| [22] |

Dutta, S.; Pati, S. K. J. Mater. Chem. 2010, 20, 8207.

doi: 10.1039/c0jm00261e |

| [23] |

Sharma, R.; Nair, N.; Strano, M. S. J. Phys. Chem. C 2009, 113, 14771.

doi: 10.1021/jp904814h |

| [24] |

Sun, J.; Iwasaki, T.; Muruganathan, M.; Mizuta, H. Appl. Phys. Lett. 2015, 106, 033509.

doi: 10.1063/1.4906609 |

| [25] |

Su, W. T.; Esfandiar, A.; Lancry, O.; Shao, J. Q.; Kumar, N.; Chaigneau, M. Chem. Commun. 2021, 57, 6895.

doi: 10.1039/D1CC01769A |

| [26] |

Wang, X.; Dai, H. Nat. Chem. 2010, 2, 661.

doi: 10.1038/nchem.719 |

| [27] |

Bai, J.; Duan, X.; Huang, Y. Nano Lett. 2009, 9, 2083.

doi: 10.1021/nl900531n |

| [28] |

Xu, W. T.; Seo, H. K.; Min, S. Y.; Cho, H.; Lim, T. S.; Oh, C. Y.; Lee, Y.; Lee, T. W. Adv. Mater. 2014, 26, 3459.

doi: 10.1002/adma.v26.21 |

| [29] |

Jeon, S.; Han, P.; Jeong, J.; Hwang, W. S.; Hong, S. W. Nanomaterials 2020, 11, 33.

doi: 10.3390/nano11010033 |

| [30] |

Pan, Z.; Liu, N.; Fu, L.; Liu, Z. J. Am. Chem. Soc. 2011, 133, 17578.

doi: 10.1021/ja207517u |

| [31] |

Zhang, X. W.; Yazyev, O. V.; Feng, J. J.; Xie, L. M.; Tao, C. G.; Chen, Y. C.; Jiao, L. Y.; Pedramrazi, Z.; Zettl, A.; Louie, S. G.; Dai, H. J.; Crommie, M. F. ACS Nano 2013, 7, 198.

doi: 10.1021/nn303730v |

| [32] |

Wu, S.; Liu, B.; Shen, C.; Li, S.; Huang, X. C.; Lu, X. B.; Chen, P.; Wang, G. L.; Wang, D. M.; Liao, M. Z.; Zhang, J.; Zhang, T. T.; Wang, S. P.; Yang, W.; Yang, R.; Shi, D. X.; Watanabe, K. J.; Taniguchi, T.; Yao, Y. G.; Wang, W. H.; Zhang, G. Y. Phys. Rev. Lett. 2018, 120, 216601.

doi: 10.1103/PhysRevLett.120.216601 |

| [33] |

Iberi, V.; Ievlev, A. V.; Vlassiouk, I.; Jesse, S.; Kalinin, S. V.; Joy, D. C.; Rondinone, A. J.; Belianinov, A.; Ovchinnikova, O. S. Nanotechnology 2016, 27, 125302.

doi: 10.1088/0957-4484/27/12/125302 |

| [34] |

Lemme, M. C.; Bell, D. C.; Williams, J. R.; Stern, L. A.; Baugher, B. W. H.; Jarillo Herrero, P.; Marcus, C. M. ACS Nano 2009, 3, 2674.

doi: 10.1021/nn900744z pmid: 19769403 |

| [35] |

Abbas, A. N.; Liu, G.; Liu, B. L.; Zhang, L. Y.; Liu, H.; Ohlberg, D.; Wu, W.; Zhou, C. W. ACS Nano 2014, 8, 1538.

doi: 10.1021/nn405759v |

| [36] |

Levente, T.; Gergely, D.; Philippe, L.; Laszlo, P. B. Nat. Nanotechnol. 2008, 3, 397.

doi: 10.1038/nnano.2008.149 |

| [37] |

Ci, L.; Xu, Z.; Wang, L.; Gao, W.; Ding, F.; Kelly, K. F.; Yakobson, B. I.; Ajayan, P. M. Nano Res. 2008, 1, 116.

doi: 10.1007/s12274-008-8020-9 |

| [38] |

Campos, L. C.; Manfrinato, V. R.; Sanchez Yamagishi, J. D.; Kong, J; Jarillo Herrero, P. Nano Lett. 2009, 9, 2600.

doi: 10.1021/nl900811r |

| [39] |

Freitag, M. Nat. Nanotechnol. 2008, 3, 455.

doi: 10.1038/nnano.2008.219 pmid: 18685628 |

| [40] |

Qiu, Z. Y.; Song, L.; Zhao, J.; Li, Z. Y.; Yang, J. L. Angew. Chem. Int. Ed. 2016, 55, 9918.

doi: 10.1002/anie.201602541 |

| [41] |

Schäffel, F.; Warner, J. H.; Bachmatiuk, A.; Rellinghaus, B.; Büchner, B.; Schultz, L.; Rümmeli, M. H. Phys. Status Solidi B 2009, 246, 2540.

doi: 10.1002/pssb.200982293 |

| [42] |

Jin, J. E.; Lee, J. H.; Choi, J. H.; Jang, H. K.; Na, J.; Whang, D.; Kim, D. H.; Kim, G. T. Phys. Chem. Chem. Phys. 2016, 18, 101.

doi: 10.1039/C5CP03139G |

| [43] |

Ta, H. Q.; Bachmatiuk, A.; Warner, J. H.; Zhao, L.; Sun, Y.; Zhao, J.; Gemming, T.; Trzebicka, B.; Liu, Z.; Pribat, D.; Rümmeli, M. H. ACS Nano 2016, 10, 6323.

doi: 10.1021/acsnano.6b02625 |

| [44] |

Kosynkin, D. V.; Higginbotham, A. L.; Sinitskii, A.; Lomeda, J. R.; Dimiev, A.; Price, B. K.; Tour, J. M. Nature 2009, 458, 872.

doi: 10.1038/nature07872 |

| [45] |

Higginbotham, A. L.; Kosynkin, D. V.; Sinitskii, A.; Sun, Z. Z.; Tour, J. M. ACS Nano 2010, 4, 2059.

doi: 10.1021/nn100118m pmid: 20201538 |

| [46] |

Elias, A. L.; Botello-Mendez, A. R.; Meneses-Rodriguez, D.; Jehova Gonzalez, V.; Ramirez-Gonzalez, D.; Ci, L.; Munoz-Sandoval, E.; Ajayan, P. M.; Terrones, H.; Terrones, M. Nano Lett. 2010, 10, 366.

doi: 10.1021/nl901631z |

| [47] |

Jiao, L.; Zhang, L.; Wang, X. R.; Diankov, G.; Dai, H. J. Nature 2009, 458, 877.

doi: 10.1038/nature07919 |

| [48] |

Morelos-Gomez, A.; Vega-Diaz, S. M.; Gonzalez, V. J.; Tristan- Lopez, F.; Cruz-Silva, R.; Fujisawa, K.; Muramatsu, H.; Hayashi, T.; Mi, X.; Shi, Y. F. ACS Nano 2012, 6, 2261.

doi: 10.1021/nn2043252 pmid: 22360783 |

| [49] |

Fan, Y. C.; Li, J. L.; Liu, X.; Wang, L. J.; Chen, X. H.; Sun, S. K.; Kawasaki, A.; Jiang, W. Carbon 2011, 49, 1439.

doi: 10.1016/j.carbon.2010.12.013 |

| [50] |

Kim, K.; Sussman, A.; Zettl, A. ACS Nano 2010, 4, 1362.

doi: 10.1021/nn901782g |

| [51] |

Hu, X. L.; Hu, Y. Z.; Huang, J. D.; Zhou, N.; Liu, Y. H.; Wei, L.; Chen, X.; Zhuang, N. F. Nanotechnology 2018, 29, 145705.

doi: 10.1088/1361-6528/aaac1d |

| [52] |

Terrones, M.; Botello-Méndez, A. R.; Campos-Delgado, J.; López-Urías, F.; Vega-Cantú, Y. I.; Rodríguez-Macías, F. J.; Elías, A. L.; Muñoz-Sandoval, E.; Cano-Márquez, A. G.; Charlier, J.-C. Nano Today 2010, 5, 351.

doi: 10.1016/j.nantod.2010.06.010 |

| [53] |

Cai, J. M.; Ruffieux, P.; Jaafar, R.; Bieri, M.; Braun, T.; Blankenburg, S.; Muoth, M.; Seitsonen, A. P.; Saleh, M.; Feng, X. L.; Müllen, K.; Fasel, R. Nature 2010, 466, 470.

doi: 10.1038/nature09211 |

| [54] |

Blankenburg, S.; Cai, J. M.; Ruffieux, P.; Jaafer, R.; Passerone, D.; Feng, X. L.; Mullen, K.; Fasel, R.; Pignedoli, C. A. J. Am. Chem. Soc. 2012, 6, 2020.

|

| [55] |

Nguyen, G. D.; Toma, F. M.; Cao, T.; Pedramrazi, Z.; Chen, C.; Rizzo, D. J.; Joshi, T.; Bronner, C.; Chen, Y.-C.; Favaro, M. J. Phys. Chem. C 2016, 120, 2684.

doi: 10.1021/acs.jpcc.5b09986 |

| [56] |

Yang, W. L.; Lucotti, A.; Tommasini, M.; Chalifoux, W. A. J. Am. Chem. Soc. 2016, 138, 9137.

doi: 10.1021/jacs.6b03014 |

| [57] |

Nguyen, T. C.; Aluru, N. R. Comput. Mater. Sci. 2023, 216, 111814.

doi: 10.1016/j.commatsci.2022.111814 |

| [58] |

Kolmer, M.; Zuzak, R.; Steiner, A. K.; Zajac, L.; Engelund, M.; Godlewski, S.; Szymonski, M.; Amsharov, K. Science 2019, 363, 57.

doi: 10.1126/science.aav4954 pmid: 30606840 |

| [59] |

Sakaguchi, H.; Kawagoe, Y.; Hirano, Y.; Iruka, T.; Yano, M.; Nakae, T. Adv. Mater. 2014, 26, 4134.

doi: 10.1002/adma.v26.24 |

| [60] |

Chen, Z. P.; Zhang, W.; Palma, C. A.; Lodi Rizzini, A.; Liu, B. L.; Abbas, A.; Richter, N.; Martini, L.; Wang, X. Y.; Cavani, N. J. Am. Chem. Soc. 2016, 138, 15488.

doi: 10.1021/jacs.6b10374 |

| [61] |

Fu, Y. B.; Yang, H.; Gao, Y. X.; Huang, L.; Berger, R.; Liu, J. Z.; Lu, H. L.; Cheng, Z. H.; Du, S. X.; Gao, H. J.; Feng, X. L. Angew. Chem. Int. Ed. 2020, 59, 8873.

doi: 10.1002/anie.v59.23 |

| [62] |

Timothy, H. V.; Mikhail, S.; Donna, A. K.; Martha, D. M.; Eric, B.; Lingmei, K.; Peter, M. W.; Peter, A. D.; Axel, E.; Alexander, S. Nat. Commun. 2014, 5, 3189.

doi: 10.1038/ncomms4189 pmid: 24510014 |

| [63] |

Huang, Y. J.; Mai, Y. Y.; Beser, U.; Teyssandier, J.; Velpula, G.; van Gorp, H.; Straaso, L. A.; Hansen, M. R.; Rizzo, D.; Casiraghi, C. J. Am. Chem. Soc. 2016, 138, 10136.

doi: 10.1021/jacs.6b07061 |

| [64] |

Yang, L.; Zheng, W. H.; Osella, S.; Droste, J.; Komber, H.; Liu, K.; Bockmann, S.; Beljonne, D.; Hansen, M. R.; Bonn, M.; Wang, H. I.; Liu, J. Z.; Feng, X. L. Adv. Sci. 2022, 9, 2200708.

doi: 10.1002/advs.v9.19 |

| [65] |

Liu, Z. Y.; Hu, Y. B.; Zheng, W. H.; Wang, C.; Baaziz, W.; Richard, F.; Ersen, O.; Bonn, M.; Wang, H. I.; Narita, A.; Ciesielski, A.; Mullen, K.; Samori, P. Adv. Funct. Mater. 2022, 32, 2109543.

doi: 10.1002/adfm.v32.16 |

| [66] |

Karakachian, H.; Nguyen, T. T. N.; Aprojanz, J.; Zakharov, A. A.; Yakimova, R.; Rosenzweig, P.; Polley, C. M.; Balasubramanian, T.; Tegenkamp, C.; Power, S. R. Nat. Commun. 2020, 11, 6380.

doi: 10.1038/s41467-020-19051-x pmid: 33311455 |

| [67] |

Aprojanz, J.; Power, S. R.; Bampoulis, P.; Roche, S.; Jauho, A. P.; Zandvliet, H. J. W.; Zakharov, A. A.; Tegenkamp, C. Nat. Commun. 2018, 9, 4426.

doi: 10.1038/s41467-018-06940-5 |

| [68] |

Sprinkle, M.; Ruan, M.; Hu, Y.; Hankinson, J.; Rubio-Roy, M.; Zhang, B.; Wu, X.; Berger, C.; de Heer, W. A. Nat. Nanotechnol. 2010, 5, 727.

doi: 10.1038/nnano.2010.192 pmid: 20890273 |

| [69] |

Galves, L. A.; Wofford, J. M.; Soares, G. V.; Jahn, U.; Pfüller, C.; Riechert, H.; Lopes, J. M. J. Carbon 2017, 115, 162.

doi: 10.1016/j.carbon.2017.01.018 |

| [70] |

Copetti, G.; Nunes, E. H.; Feijo, T. O.; Galves, L. A.; Heilmann, M.; Soares, G. V.; Lopes, J. M. J.; Radtke, C. Nanotechnology 2021, 32, 145707.

doi: 10.1088/1361-6528/abd43a |

| [71] |

Dedkov, Y. S.; Fonin, M.; Laubschat, C. Appl. Phys. Lett. 2008, 92, 052506.

doi: 10.1063/1.2841809 |

| [72] |

Chen, Q.; Song, Q.; Yi, X.; Chen, Q.; Wu, W.; Huang, M.; Zhao, C.; Wang, S.; Zhu, H. Sci. China Mater. 2020, 63, 1973.

doi: 10.1007/s40843-020-1394-3 |

| [73] |

Kastorp, C. F. P.; Duncan, D. A.; Scheffler, M.; Thrower, J. D.; Jorgensen, A. L.; Hussain, H.; Lee, T. L.; Hornekaer, L.; Balog, R. Nanoscale 2020, 12, 19776.

doi: 10.1039/D0NR04788K |

| [74] |

Sutter, P.; Sadowski, J. T.; Sutter, E. Phys. Rev. B 2009, 80, 245411.

doi: 10.1103/PhysRevB.80.245411 |

| [75] |

Sicot, M.; Bouvron, S.; Zander, O.; Rüdiger, U.; Dedkov, Y. S.; Fonin, M. Appl. Phys. Lett. 2010, 96, 093115.

doi: 10.1063/1.3341176 |

| [76] |

Kazi, H.; Cao, Y.; Tanabe, I.; Driver, M. S.; Dowben, P. A.; Kelber, J. A. Mater. Res. Express 2014, 1, 035601.

doi: 10.1088/2053-1591/1/3/035601 |

| [77] |

Mohamad Yunus, R.; Miyashita, M.; Tsuji, M.; Hibino, H.; Ago, H. Chem. Mater. 2014, 26, 5215.

doi: 10.1021/cm501854r |

| [78] |

Jacobberger, R. M.; Kiraly, B.; Fortin-Deschenes, M.; Levesque, P. L.; McElhinny, K. M.; Brady, G. J.; Rojas Delgado, R.; Singha Roy, S.; Mannix, A.; Lagally, M. G. Nat. Commun. 2015, 6, 8006.

doi: 10.1038/ncomms9006 pmid: 26258594 |

| [79] |

Sun, H. B.; Liu, F. N.; Zhang, L. N.; McLean, B.; An, H.; Kim, S.; Suh, J.; Wang, Z. J.; Ding, F. Adv. Funct. Mater. 2022, 32, 2206961.

doi: 10.1002/adfm.v32.40 |

| [80] |

Jacobberger, R. M.; Arnold, M. S. ACS Nano 2017, 11, 8924.

doi: 10.1021/acsnano.7b03220 pmid: 28880526 |

| [81] |

Way, A. J.; Murray, E. A.; Goltl, F.; Saraswat, V.; Jacobberger, R. M.; Mavrikakis, M.; Arnold, M. S. J. Phys. Chem. Lett. 2019, 10, 4266.

doi: 10.1021/acs.jpclett.9b01079 |

| [82] |

Way, A. J.; Jacobberger, R. M.; Arnold, M. S. Nano Lett. 2018, 18, 898.

doi: 10.1021/acs.nanolett.7b04240 |

| [83] |

Way, A. J.; Jacobberger, R. M.; Guisinger, N. P.; Saraswat, V.; Zheng, X.; Suresh, A.; Dwyer, J. H.; Gopalan, P.; Arnold, M. S. Nat. Commun. 2022, 13, 2992.

doi: 10.1038/s41467-022-30563-6 |

| [84] |

Kim, H. W.; Joo, W.-J.; Jang, W.-J.; Kim, S. H. Physica E Low Dimens. Syst. 2023, 146, 115531.

|

| [85] |

Cai, L.; He, W.; Xue, X.; Huang, J.; Zhou, K.; Zhou, X.; Xu, Z.; Yu, G. Natl. Sci. Rev. 2021, 12, 37.

|

| [86] |

Wei, D. C.; Liu, Y. Q.; Zhang, H. L.; Huang, L. P.; Wu, B.; Chen, J. Y.; Yu, G. J. Am. Chem. Soc. 2009, 131, 11147.

doi: 10.1021/ja903092k |

| [87] |

Kato, T.; Hatakeyama, R. Nat. Nanotechnol. 2012, 7, 651.

doi: 10.1038/nnano.2012.145 |

| [88] |

Martin-Fernandez, I.; Wang, D. B.; Zhang, Y. G. Nano Lett. 2012, 12, 6175.

doi: 10.1021/nl302993m pmid: 23134072 |

| [89] |

Chen, L. X.; He, L.; Wang, H. S.; Wang, H. M.; Tang, S. J.; Cong, C. X.; Xie, H.; Li, L.; Xia, H.; Li, T. X.; Wu, T. R.; Zhang, D. L.; Deng, L. W.; Yu, T.; Xie, X. M.; Jiang, M. H. Nat. Commun. 2017, 8, 14703.

doi: 10.1038/ncomms14703 |

| [90] |

Xiong, X. Y.; Ning, C. C.; Jin, Y.; Li, D. L.; Yang, Q.; Gong, X. N.; Cheng, C.; Pan, Q. J.; Xu, Y.; Hu, B. S. Carbon 2022, 191, 571.

doi: 10.1016/j.carbon.2022.02.035 |

| [91] |

Liang, X. G.; Wi, S. ACS Nano 2012, 6, 9700.

doi: 10.1021/nn303127y |

| [92] |

Jeong, S. J.; Jo, S.; Lee, J.; Yang, K.; Lee, H.; Lee, C. S.; Park, H.; Park, S. Nano Lett. 2016, 16, 5378.

doi: 10.1021/acs.nanolett.6b01542 |

| [93] |

Hwang, W. S.; Tahy, K.; Nyakiti, L. O.; Wheeler, V. D.; Myers- Ward, R. L.; Eddy, C. R.; Gaskill, D. K.; Xing, H. L.; Seabaugh, A.; Jena, D. J. Vac. Sci. Technol. B 2012, 30, 03D104.

doi: 10.1116/1.3693593 |

| [94] |

Hwang, W. S.; Zhao, P.; Tahy, K.; Nyakiti, L. O.; Wheeler, V. D.; Myers-Ward, R. L.; Eddy, C. R.; Gaskill, D. K.; Robinson, J. A.; Haensch, W.; Xing, H. L.; Seabaugh, A.; Jena, D. APL Mater. 2015, 3, 011101.

doi: 10.1063/1.4905155 |

| [95] |

Bennett, P. B.; Pedramrazi, Z.; Madani, A.; Chen, Y. C.; de Oteyza, D. G.; Chen, C.; Fischer, F. R.; Crommie, M. F.; Bokor, J. Appl. Phys. Lett. 2013, 103, 254114.

|

| [96] |

Linas, J. P.; Fairbrother, A.; Brain, G. B.; Shi, W.; Lee, K.; Wu, S.; Choi, B. Y.; Braganza, R.; Lear, J.; Kau, N.; Choi, W.; Chen, C.; Pedramrazi, Z.; Dumslaff, T.; Narita, A.; Feng, X. L.; Mullen, K.; Fischer, F.; Zettl, A.; Ruffieux, P.; Yablonovitch, E.; Crommie, M.; Fasel, R.; Bokor, J. Nat. Commun. 2017, 8, 633.

doi: 10.1038/s41467-017-00734-x |

| [97] |

Brain, G. B.; Sun, Q.; Giovannantonio, M. D.; Du, C. Z.; Wang, X. Y.; Linas, J. P.; Mutlu, Z.; Lin, Y. X.; Wihelm, J.; Overbeck, J.; Daniels, C.; Lamparski, M.; Sahabudeen, H.; Perrin, M. L.; Urgel, J. I.; Mishra, S.; Kinikar, A.; Widmer, R.; Stolz, S.; Bommert, M.; Pignedoli, C.; Feng, X. L.; Calame, M.; Mullen, K.; Narita, A.; Meunier, V.; Bokor, J.; Fasel, R.; Ruffieux, P. Small 2022, 18, 2202301.

doi: 10.1002/smll.v18.31 |

| [98] |

Ye, Y.; Gan, L.; Dai, L.; Meng, H.; Wei, F.; Dai, Y.; Shi, Z. J.; Yu, B.; Guo, X. F.; Qin, G. G. J. Mater. Chem. 2011, 21, 11760.

doi: 10.1039/c1jm11441g |

| [99] |

Moradian, R.; Mohammadi, Y.; Ghobadi, N. J. Phys. Condens. Mat. 2008, 20, 425211.

doi: 10.1088/0953-8984/20/42/425211 |

| [100] |

Wang, Y.; Yang, R.; Shi, Z. W.; Zhang, L. C.; Shi, D. X.; Wang, E.; Zhang, G. Y. ACS Nano 2011, 5, 3645.

doi: 10.1021/nn103523t pmid: 21452882 |

| [101] |

Martín, A.; Hernández-Ferrer, J.; Martínez, M. T.; Escarpa, A. Electrochim. Acta 2015, 172, 2.

doi: 10.1016/j.electacta.2014.11.090 |

| [102] |

Wu, S.; Lan, X. Q.; Huang, F. F.; Luo, Z. Z.; Ju, H. X.; Meng, C. G.; Duan, C. Y. Biosens. Bioelectron. 2012, 32, 293.

doi: 10.1016/j.bios.2011.12.006 |

| [103] |

Asadian, E.; Shahrokhian, S.; Zad, A. I.; Jokar, E. Sensor. Actuat. B: Chem. 2014, 196, 582.

doi: 10.1016/j.snb.2014.02.049 |

| [104] |

Martin, A.; Batalla, P.; Hernandez-Ferrer, J.; Martinez, M. T.; Escarpa, A. Biosens. Bioelectron. 2015, 68, 163.

doi: 10.1016/j.bios.2014.12.030 |

| [105] |

Ismail, N. S.; Le, Q. H.; Yoshikawa, H.; Saito, M.; Tamiya, E. Electrochim. Acta 2014, 146, 98.

doi: 10.1016/j.electacta.2014.08.123 |

| [106] |

Huang, B.; Li, Z. Y.; Liu, Z. R.; Zhou, G.; Hao, S. G.; Wu, J.; Gu, B. L.; Duan, W. H. J. Phys. Chem. C 2008, 112, 13442.

doi: 10.1021/jp8021024 |

| [107] |

Shekhirev, M.; Lipatov, A.; Torres, A.; Vorobeva, N. S.; Harkleroad, A.; Lashkov, A.; Sysoev, V.; Sinitskii, A. ACS Appl. Mater. Interfaces 2020, 12, 7392.

doi: 10.1021/acsami.9b13946 |

| [108] |

Salih, E.; Ayesh, A. I. Sensors 2020, 20, 3932.

doi: 10.3390/s20143932 |

| [109] |

Ali, M.; Khan, S.; Awwad, F.; Tit, N. Appl. Surf. Sci. 2020, 514, 145866.

doi: 10.1016/j.apsusc.2020.145866 |

| [110] |

Jiang, J. W.; Wang, J. S.; Li, B. W. Nanoscale 2010, 2, 2864.

doi: 10.1039/c0nr00437e |

| [111] |

Nelson, T.; Zhang, B.; Prezhdo, O. V. Nano Lett. 2010, 10, 3237.

doi: 10.1021/nl9035934 |

| [1] | 刘洋, 高丰琴, 马占营, 张引莉, 李午戊, 侯磊, 张小娟, 王尧宇. 一例钴基金属有机框架化合物活化过氧单硫酸盐高效降解水中亚甲基蓝研究[J]. 化学学报, 2024, 82(2): 152-159. |

| [2] | 何文, 王波, 冯晗俊, 孔祥如, 李桃, 肖睿. CO2捕集膜分离的Pebax基材料研究进展[J]. 化学学报, 2024, 82(2): 226-241. |

| [3] | 张凯, 武晓君. 具有室温铁磁性的二维Janus钛硫属化物★[J]. 化学学报, 2023, 81(9): 1142-1147. |

| [4] | 张正初, 熊炜, 吕华. α-螺旋聚氨基酸交联的水凝胶的制备和材料特性★[J]. 化学学报, 2023, 81(9): 1113-1119. |

| [5] | 杨蓉婕, 周璘, 苏彬. 基于共价有机框架修饰电极的维生素A和C的选择性检测★[J]. 化学学报, 2023, 81(8): 920-927. |

| [6] | 崔国庆, 胡溢玚, 娄颖洁, 周明霞, 李宇明, 王雅君, 姜桂元, 徐春明. CO2加氢制醇类催化剂的设计制备及性能研究进展[J]. 化学学报, 2023, 81(8): 1081-1100. |

| [7] | 刘佳, 陈光海, 陈轶群, 江杰涛, 肖霄, 吴强, 杨立军, 王喜章, 胡征. 碳热还原活化扩孔提升介观结构碳纳米笼超级电容器性能★[J]. 化学学报, 2023, 81(7): 709-716. |

| [8] | 张玉莹, 蔡潇, 胡维刚, 李光俊, 祝艳. Pd和Hg共掺杂的金属纳米团簇HgPdAu23(PET)18★[J]. 化学学报, 2023, 81(7): 703-708. |

| [9] | 梁雪峰, 荆剑, 冯昕, 赵勇泽, 唐新员, 何燕, 张立胜, 李慧芳. 共价有机框架COF66/COF366的电子结构: 从单体到二维平面聚合物[J]. 化学学报, 2023, 81(7): 717-724. |

| [10] | 刘嘉文, 林玮璜, 王惟嘉, 郭学益, 杨英. Cu1.94S-SnS纳米异质结的合成及其光催化降解研究[J]. 化学学报, 2023, 81(7): 725-734. |

| [11] | 胡立伟, 刘宪虎, 刘春太, 宋延林, 李明珠. 光子晶体结构色材料的自组装制备与应用★[J]. 化学学报, 2023, 81(7): 809-819. |

| [12] | 赵天成, 蒋鸿宇, 张琨, 徐一帆, 康欣悦, 胥鉴宸, 周旭峰, 陈培宁, 彭慧胜. 基于环烷烃/乙醇混合碳源高性能碳纳米管纤维的连续化制备[J]. 化学学报, 2023, 81(6): 565-571. |

| [13] | 陈剑, 蔡卓尔, 焦淑琳, 张祥, 胡进忠, 刘敏, 孙伯旺, 花秀妮. 一种热响应介电开关型零维有机-无机杂化材料: (C3H6NH2)2CoCl4[J]. 化学学报, 2023, 81(5): 480-485. |

| [14] | 贾洋刚, 陈诗洁, 邵霞, 程婕, 林娜, 方道来, 冒爱琴, 李灿华. 高性能无钴化钙钛矿型高熵氧化物负极材料的制备及储锂性能研究[J]. 化学学报, 2023, 81(5): 486-495. |

| [15] | 高丰琴, 刘洋, 张引莉, 蒋育澄. 羧基功能化Fe3O4固定化酶反应器的构筑及性能研究[J]. 化学学报, 2023, 81(4): 338-344. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||