化学学报 ›› 2022, Vol. 80 ›› Issue (1): 49-55.DOI: 10.6023/A21080402 上一篇 下一篇

研究论文

郝肖柯a,b, 翟振宇a,b, 孙亚昕a,b, 李从举a,b,*( )

)

投稿日期:2021-08-26

发布日期:2021-10-22

通讯作者:

李从举

基金资助:

Xiaoke Haoa,b, Zhenyu Zhaia,b, Yaxin Suna,b, Congju Lia,b( )

)

Received:2021-08-26

Published:2021-10-22

Contact:

Congju Li

Supported by:文章分享

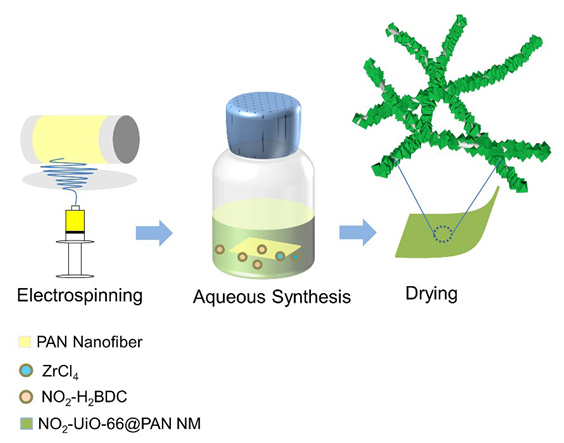

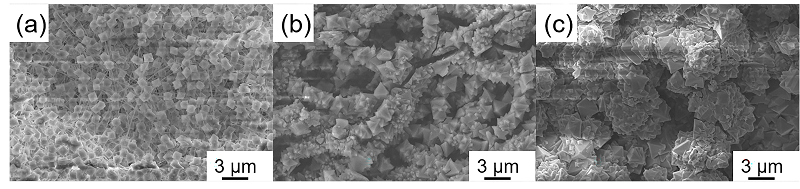

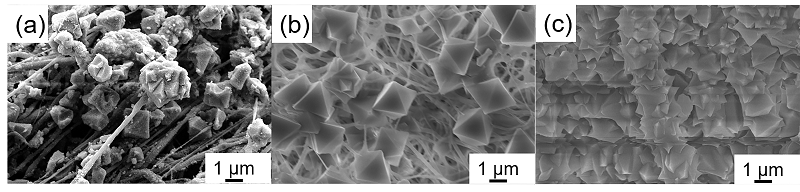

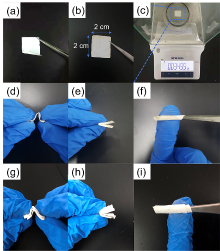

柔性高吸附性材料在废水废气处理、防护服制造、有毒有害物质监测等诸多领域中发挥着关键的作用. 本工作采用水相合成的方法, 以三氟乙酸(trifluoroacetic acid, TFA)为结构导向剂, 以水为溶剂, 在静电纺纳米纤维上原位生长了金属有机框架材料NO2-UiO-66, 制备了NO2-UiO-66@PAN(聚丙烯腈)柔性纳米纤维膜材料. 并研究了不同配比的三氟乙酸/去离子水、不同的金属盐与有机配体比例以及水热生长时间对NO2-UiO-66形貌和负载效果的影响. 最佳TFA添加含量为φTFA=30%, 金属盐与配体物质的量比为1∶1.5, 水热生长时间为4 h. 采用扫描电子显微镜(scanning electron microscope, SEM)、X射线衍射(X-ray diffraction, XRD)、傅里叶红外光谱(Fourier transform infrared spectroscopy, FT-IR)、热重(thermogravimetry, TG)分析及氮气吸附-脱附测试对NO2-UiO-66@PAN纳米纤维膜结构进行了表征. 结果表明, NO2-UiO-66均匀地负载在了纳米纤维上, 负载量可达33.28%, 比表面积为504.16 m2/g、孔体积为0.241 cm3/g. 并且在经过高温(320 ℃)、弯折和水、酸、碱洗涤后仍能保持结构的稳定性. 通过以上表征分析, 发现将NO2-UiO-66负载在纳米纤维上能够得到物理和化学稳定性质优异的膜材料, 在有毒有害等恶劣条件下有很大的应用潜力.

郝肖柯, 翟振宇, 孙亚昕, 李从举. 柔性可水洗的Zr-MOFs复合纳米纤维薄膜的制备和性能表征[J]. 化学学报, 2022, 80(1): 49-55.

Xiaoke Hao, Zhenyu Zhai, Yaxin Sun, Congju Li. Preparation and Performance Characterization of Flexible and Washable Zr-MOFs Composite Nanofiber Membrane[J]. Acta Chimica Sinica, 2022, 80(1): 49-55.

| [1] |

Hao, X. K.; Zhang, X. L.; Zhai, Z. Y.; Li, C. J. Fine Chem. 2021, 38, 249 ; (in Chinese)

|

|

( 郝肖柯, 张秀玲, 翟振宇, 李从举, 精细化工 2021, 38, 249.)

|

|

| [2] |

Hu, M. L.; Masoomi, M. Y.; Morsali, A. Coord. Chem. Rev. 2019, 387, 415.

doi: 10.1016/j.ccr.2019.02.021 |

| [3] |

Georgiadis, A. G.; Charisiou, N.; Yentekakis, I. V.; Goula, M. A. Materials 2020, 13, 3640.

doi: 10.3390/ma13163640 |

| [4] |

Lyu, L. X.; Zhao, Y. L.; Wei, Y. Y.; Wang, H. H. Acta Chim. Sinica 2021, 79, 869 ; (in Chinese)

doi: 10.6023/A21030099 |

|

( 吕露茜, 赵娅俐, 魏嫣莹, 王海辉, 化学学报 2021, 79, 869.)

|

|

| [5] |

Zeng, J. Y.; Wang, X. S.; Zhang, X. Z.; Zhuo, R. X. Acta Chim. Sinica 2019, 77, 1156 ; (in Chinese)

doi: 10.6023/A19070259 |

|

( 曾锦跃, 王小双, 张先正, 卓仁禧, 化学学报 2019, 77, 1156.)

|

|

| [6] |

Lazaro, I. A.; Wells, C. J. R.; Forgan, R. S. Angew. Chem. Int. Ed. 2020, 59, 5211.

doi: 10.1002/anie.v59.13 |

| [7] |

He, P. C.; Zhou, J.; Zhou, A. W.; Dou, Y. B.; Li, J. R. Chem. J. Chin. Univ. 2019, 40, 855 ; (in Chinese)

|

|

( 何鹏琛, 周健, 周阿武, 豆义波, 李建荣, 高等学校化学学报, 2019, 40, 855.)

|

|

| [8] |

Wang, D. K.; Li, Z. H. Res. Chem. Intermediat. 2017, 43, 5169.

doi: 10.1007/s11164-017-3042-0 |

| [9] |

Wang, Y.; Li, B. T.; Zhang, B. C.; Tian, S. Y.; Yang, X.; Ye, H.; Xia, Z. J.; Zheng, G. X. J. Electroanal. Chem. 2020, 878, 114576.

doi: 10.1016/j.jelechem.2020.114576 |

| [10] |

Hu, R.; Zhang, X.; Chi, K. N.; Yang, T.; Yang, Y. H. ACS Appl. Mater. Inter. 2020, 12, 30770.

doi: 10.1021/acsami.0c06291 |

| [11] |

Sule, R.; Mishra, A. K. Environ. Sci. Pollut. R. 2020, 27, 16004.

doi: 10.1007/s11356-020-08299-x |

| [12] |

Wang, X. F.; Song, X. Z.; Sun, K. M.; Cheng, L.; Ma, W. Polyhedron 2018, 152, 155.

doi: 10.1016/j.poly.2018.06.037 |

| [13] |

Cui, Y. J.; Li, B.; He, H. J.; Zhou, W.; Chen, B. L.; Qian, G. D. Acc. Chem. Res. 2016, 49, 483.

doi: 10.1021/acs.accounts.5b00530 |

| [14] |

Jiao, L.; Seow, J. Y. R.; Skinner, W. S.; Wang, Z. U.; Jiang, H. L. Mater. Today 2019, 27, 43.

doi: 10.1016/j.mattod.2018.10.038 |

| [15] |

Falcaro, P.; Ricco, R.; Yazdi, A.; Imaz, I.; Furukawa, S.; Maspoch, D.; Ameloot, R.; Evans, J. D.; Doonan, C. J. Coord. Chem. Rev. 2016, 307, 237.

doi: 10.1016/j.ccr.2015.08.002 |

| [16] |

Zhang, H. B.; Nai, J. W.; Yu, L.; Lou, X. W. Joule 2017, 1, 77.

doi: 10.1016/j.joule.2017.08.008 |

| [17] |

Liu, X. L. Front. Chem. Sci. Eng. 2020, 14, 216.

doi: 10.1007/s11705-019-1857-5 |

| [18] |

Ahmad, K.; Nazir, M. A.; Qureshi, A. K.; Hussain, E.; Najam, T.; Javed, M. S.; Shah, S. S. A.; Tufail, M. K.; Hussain, S.; Khan, N. A.; Shah, H. U. R.; Ashfaq, M. Mat. Sci. Eng. B-Adv. 2020, 262, 114766.

|

| [19] |

Rada, Z. H.; Abid, H. R.; Sun, H. Q.; Shang, J.; Li, J. Y.; He, Y. D.; Liu, S. M.; Wang, S. B. Prog. Nat. Sci. 2018, 28, 160.

doi: 10.1016/j.pnsc.2018.01.016 |

| [20] |

Luu, C. L.; Nguyen, T. T. V.; Nguyen, T.; Hoang, T. C. 2015, 6, 025004.

|

| [21] |

Stassen, I.; Dou, J. H.; Hendon, C.; Dinca, M. ACS Central Sci. 2019, 5, 1425.

doi: 10.1021/acscentsci.9b00482 |

| [22] |

Taima-Mancera, I.; Rocio-Bautista, P.; Pasan, J.; Ayala, J. H.; Ruiz-Perez, C.; Afonso, A. M.; Lago, A. B.; Pino, V. Molecules 2018, 23, 2869.

doi: 10.3390/molecules23112869 |

| [23] |

Zhang, L. Y.; Chen, H.; Bai, X. J.; Wang, S.; Li, L. L.; Shao, L.; He, W. X.; Li, Y. N.; Wang, T. Q.; Zhang, X. M.; Chen, J. Y.; Fu, Y. Chem. Commun. 2019, 55, 8293.

doi: 10.1039/C9CC02614B |

| [24] |

Hong, Y.; Liu, C. Y.; Cao, X. C.; Chen, Y.; Chen, C.; Chen, Y.; Pan, Z. J. Polymers 2018, 10, 1386.

doi: 10.3390/polym10121386 |

| [25] |

Wahiduzzaman

doi: 10.1007/s11665-016-1966-y |

| [26] |

Wang, S. B.; Lin, Y.; Yang, J.; Shi, L.; Yang, G.; Zhuang, X. P.; Li, Z. H. Int. J. Hydrogen Energ. 2021, 46, 19106.

doi: 10.1016/j.ijhydene.2021.03.033 |

| [27] |

Zhai, Z. Y.; Zhang, X. L.; Wang, J. N.; Li, H. Y.; Sun, Y. X.; Hao, X. K.; Qin, Y.; Niu, B.; Li, C. J. Chem. Eng. J. 2021, 428, 131720.

doi: 10.1016/j.cej.2021.131720 |

| [28] |

Lu, A. X.; Ploskonka, A. M.; Tovar, T. M.; Peterson, G. W.; DeCoste, J. B. Ind. Eng. Chem. Res. 2017, 56, 14502.

doi: 10.1021/acs.iecr.7b04202 |

| [29] |

Ma, K. K.; Islamoglu, T.; Chen, Z. J.; Li, P.; Wasson, M. C.; Chen, Y. W.; Wang, Y. F.; Peterson, G. W.; Xin, J. H.; Farha, O. K. J. Am. Chem. Soc. 2019, 141, 15626.

doi: 10.1021/jacs.9b07301 |

| [30] |

Diring, S.; Furukawa, S.; Takashima, Y.; Tsuruoka, T.; Kitagawa, S. Chem. Mater. 2010, 22, 4531.

doi: 10.1021/cm101778g |

| [31] |

Surya, S. G.; Bhanoth, S.; Majhi, S. M.; More, Y. D.; Teja, V. M.; Chappanda, K. N. CrystEngComm 2019, 21, 7303.

doi: 10.1039/C9CE01323G |

| [32] |

Zhang, Y. Q.; Chu, Q.; Shi, Y.; Gao, J. S.; Xiong, W.; Huang, L.; Ding, Y. Acta Chim. Sinica 2021, 79, 361 ( in Chinese);

doi: 10.6023/A20100478 |

|

( 张雅祺, 楚奇, 石勇, 高金索, 熊巍, 黄磊, 丁越, 化学学报 2021, 79, 361.)

|

|

| [33] |

Shamsabadi, A. S.; Ranjbar, M.; Tavanai, H.; Farnood, A. Mater. Res. Express. 2019, 6, 055051.

doi: 10.1088/2053-1591/ab0709 |

| [34] |

Zhang, X. F.; Wang, Z. G.; Feng, Y.; Zhong, Y. X.; Liao, J. Q.; Wang, Y. Q.; Yao, J. F. Fuel 2018, 234, 256.

doi: 10.1016/j.fuel.2018.07.035 |

| [35] |

Ma, Y. L.; Liu, R. X.; Meng, S. Y.; Niu, L. T.; Yang, Z. W.; Lei, Z. Q. Acta Chim. Sinica 2019, 77, 153 ; (in Chinese)

doi: 10.6023/A18090372 |

|

( 马亚丽, 刘茹雪, 孟双艳, 牛力同, 杨志旺, 雷自强, 化学学报 2019, 77, 153.)

|

|

| [36] |

Choi, J.; Yoo, K. S.; Kim, D.; Kim, J.; Othman, M. R. ACS Appl. Nano Mater. 2021, 4, 4895.

doi: 10.1021/acsanm.1c00444 |

| [37] |

Woo, H. C.; Yoo, D. K.; Jhung, S. H. ACS Appl. Mater. Inter. 2020, 12, 28885.

doi: 10.1021/acsami.0c07123 |

| [38] |

Li, H.; Chu, H. J.; Ma, X. L.; Wang, G. R.; Liu, F. S.; Guo, M.; Lu, W. P.; Zhou, S. J.; Yu, M. Z. Chem. Eng. J. 2021, 408, 127277.

doi: 10.1016/j.cej.2020.127277 |

| [39] |

Piscopo, C. G.; Polyzoidis, A.; Schwarzer, M.; Loebbecke, S. Micropor. Mesopor. Mat. 2015, 208, 30.

doi: 10.1016/j.micromeso.2015.01.032 |

| [1] | 刘洋, 高丰琴, 马占营, 张引莉, 李午戊, 侯磊, 张小娟, 王尧宇. 一例钴基金属有机框架化合物活化过氧单硫酸盐高效降解水中亚甲基蓝研究[J]. 化学学报, 2024, 82(2): 152-159. |

| [2] | 孙博, 琚雯雯, 王涛, 孙晓军, 赵婷, 卢晓梅, 陆峰, 范曲立. 高分散共轭聚合物-金属有机框架纳米立方体的制备及抗肿瘤应用[J]. 化学学报, 2023, 81(7): 757-762. |

| [3] | 齐学平, 王飞, 张健. 后合成法构筑钛基金属有机框架及其应用[J]. 化学学报, 2023, 81(5): 548-558. |

| [4] | 殷政, 赵英博, 曾明华. 动态化学与材料和非晶物理新关联——金属有机框架玻璃的挑战、进展与新机遇[J]. 化学学报, 2023, 81(3): 246-252. |

| [5] | 陈俊畅, 张明星, 王殳凹. 晶态多孔材料合成方法的研究进展[J]. 化学学报, 2023, 81(2): 146-157. |

| [6] | 程敏, 王诗慧, 罗磊, 周利, 毕可鑫, 戴一阳, 吉旭. 面向乙烷/乙烯分离的金属有机框架膜的大规模计算筛选[J]. 化学学报, 2022, 80(9): 1277-1288. |

| [7] | 闫绍兵, 焦龙, 何传新, 江海龙. ZIF-67/石墨烯复合物衍生的氮掺杂碳限域Co纳米颗粒用于高效电催化氧还原[J]. 化学学报, 2022, 80(8): 1084-1090. |

| [8] | 闫续, 屈贺幂, 常烨, 段学欣. 金属有机框架在气体预富集、预分离及检测中的应用[J]. 化学学报, 2022, 80(8): 1183-1202. |

| [9] | 何家伟, 焦柳, 程雪怡, 陈光海, 吴强, 王喜章, 杨立军, 胡征. 金属有机框架衍生的空心碳纳米笼的结构调控与锂硫电池性能研究[J]. 化学学报, 2022, 80(7): 896-902. |

| [10] | 牛犇, 翟振宇, 郝肖柯, 任婷莉, 李从举. 基于ZIF-8/PAN复合薄膜的柔性丙酮气体传感器[J]. 化学学报, 2022, 80(7): 946-955. |

| [11] | 曹琳安, 魏敏. 电子导电金属有机框架薄膜的研究进展[J]. 化学学报, 2022, 80(7): 1042-1056. |

| [12] | 谢晨帆, 徐玉平, 高明亮, 徐忠宁, 江海龙. MOF基Pd单位点催化CO酯化制碳酸二甲酯[J]. 化学学报, 2022, 80(7): 867-873. |

| [13] | 耿元昊, 林小秋, 孙亚昕, 李惠雨, 秦悦, 李从举. 双金属导电金属有机框架材料Ni/Co-CAT的制备及其氧还原催化性能研究[J]. 化学学报, 2022, 80(6): 748-755. |

| [14] | 王诗慧, 薛小雨, 程敏, 陈少臣, 刘冲, 周利, 毕可鑫, 吉旭. 机器学习与分子模拟协同的CH4/H2分离金属有机框架高通量计算筛选[J]. 化学学报, 2022, 80(5): 614-624. |

| [15] | 张容, 柳江萍, 朱子怡, 陈淑妹, 王飞, 张健. 二茂铁功能化的两例镉金属有机框架材料的合成、结构和表征※[J]. 化学学报, 2022, 80(3): 249-254. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||