化学学报 ›› 2021, Vol. 79 ›› Issue (2): 200-207.DOI: 10.6023/A20090428 上一篇 下一篇

研究论文

李燕丽1, 于丹丹1, 林森1, 孙东飞1,*( ), 雷自强1(

), 雷自强1( )

)

投稿日期:2020-09-16

发布日期:2020-12-18

通讯作者:

孙东飞

作者简介:基金资助:

Yanli Li1, Dandan Yu1, Sen Lin1, Dongfei Sun1,*( ), Ziqiang Lei1(

), Ziqiang Lei1( )

)

Received:2020-09-16

Published:2020-12-18

Contact:

Dongfei Sun

Supported by:文章分享

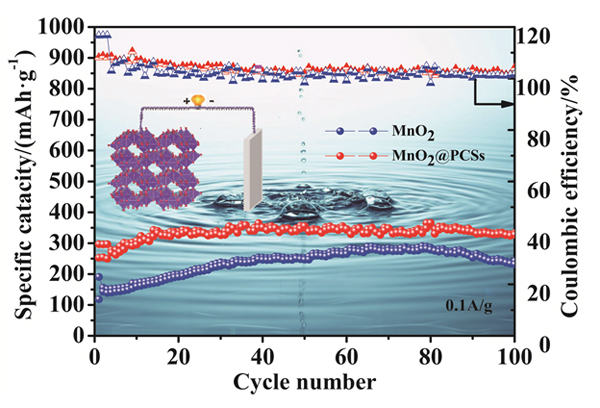

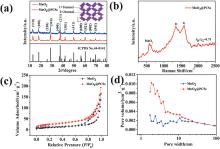

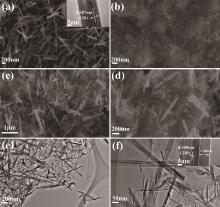

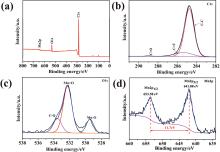

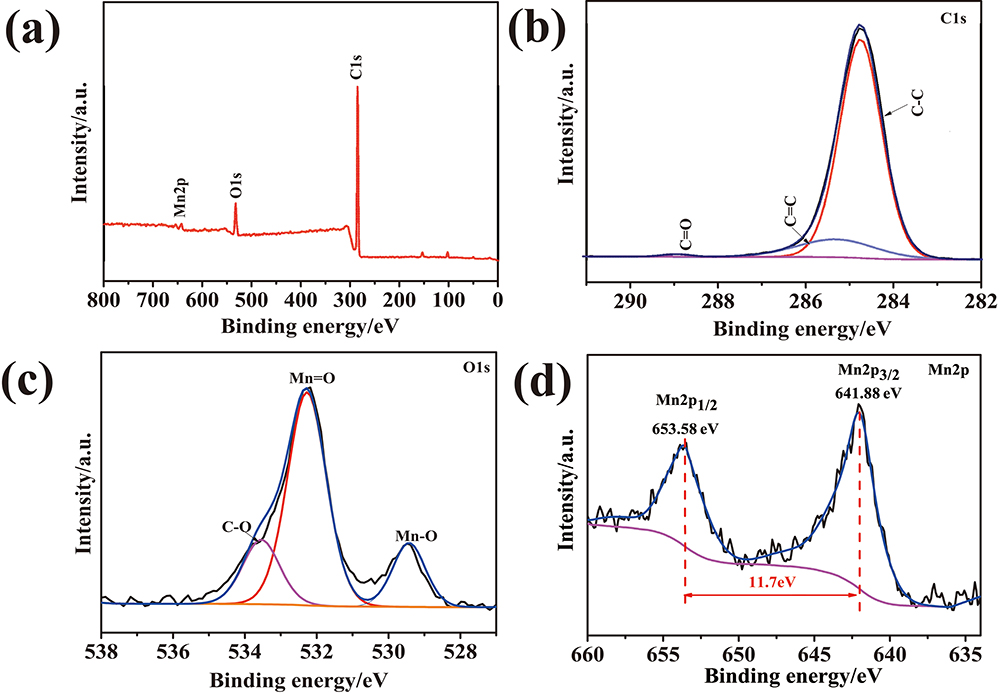

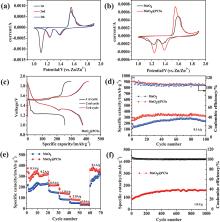

针对水系锌离子电池锰基正极材料存在比容量低、循环稳定性差等问题, 本工作利用水热法制备出棒状结构的α-MnO2, 通过柠檬酸钠高温碳化制备多孔碳, 进而通过超声分散等处理制备出α-MnO2/PCSs复合材料. 三维的多孔网络有助于提高电子导电性, 提供一个稳定的支撑;α-MnO2纳米棒均匀地附着在多孔碳纳米片层表面, 有效地避免α-MnO2的团聚, 从而提高锌离子传输效率. 得益于α-MnO2/PCSs独特的结构优势, 将其作为锌离子电池正极材料, 在电流密度为0.1 A•g–1的条件下循环100次后, 其可逆容量为350 mAh•g–1, 在1 A•g–1的大的电流密度下, 经过1000圈循环后, 容量可达160 mAh•g–1, 展现了优异的循环稳定性能, 有望成为高性能锌离子电池的潜在正极材料.

李燕丽, 于丹丹, 林森, 孙东飞, 雷自强. α-MnO2纳米棒/多孔碳正极材料的制备及水系锌离子电池性能研究[J]. 化学学报, 2021, 79(2): 200-207.

Yanli Li, Dandan Yu, Sen Lin, Dongfei Sun, Ziqiang Lei. Preparation of α-MnO2 Nanorods/Porous Carbon Cathode for Aqueous Zinc-ion Batteries[J]. Acta Chimica Sinica, 2021, 79(2): 200-207.

| [1] |

Yabuuchi N.; Kubota K.; Dahbi M.; Komaba S. Chem. Rev. 2014, 114, 11636.

|

| [2] |

Hu X.F.; Sun J.C.; Li Z.F.; Zhao Q.; Chen C.C.; Chen J. Angew. Chem. Int. Ed. 2016, 128, 6592.

|

| [3] |

Wang L.; Zhao D.-D.; Liu X.; Yu P.; Fu H.G. Acta Chim. Sinica 2017, 75, 231. (in Chinese)

|

|

王蕾, 赵冬冬, 刘旭, 于鹏, 付宏刚, 化学学报, 2017, 75, 231.

|

|

| [4] |

Ren T.; Zhuang Q.C.; Hao Y.W.; Cui Y.L. Acta Chim. Sinica 2016, 74, 833. (in Chinese)

|

|

任彤, 庄全超, 郝玉婉, 崔永丽, 化学学报, 2016, 74, 833.

|

|

| [5] |

Zhao Q.; Yan Z.H.; Chen C.C.; Chen J. Chem. Rev. 2017, 117, 10121.

|

| [6] |

Lee J.; Ju J.B.; Cho W.I.; Cho B.W.; Oh S.H. Electrochim. Acta 2013, 112, 138.

|

| [7] |

Lee B.; Lee H.R.; Kim H.; Chung K.Y.; Cho B.W.; Oh S.H. Chem. Commun. 2015, 51, 9265.

|

| [8] |

Häupler B.; Rössel C.; Schwenke A.M.; Winsberg J.; Schmidt D.; Wild A.; Schubert U.S. NPG Asia Mater. 2016, 8, e283.

|

| [9] |

Xu D.W.; Li B.H.; Wei C.G.; He Y.B.; Du H.D.; Chu X.D.; Qin X.Y.; Yang Q.H.; Kang F.Y. Electrochim. Acta 2014, 133, 254.

|

| [10] |

Li H.F.; Xu C.J.; Han C.P.; Chen Y.Y.; Wei C.G.; Li B.H.; Kang F.Y. J. Electrochem. Soc. 2015, 162, A1439.

|

| [11] |

Lee B.; Yoon K.; Seo C.R.; Cho B.W.; Lee H.R.; Yoon C.S.; Oh S.H. ChemSusChem 2016, 9, 2948.

|

| [12] |

Xu C.J.; Du H.D.; Li B.H.; Kang F.Y.; Zeng Y.Q. Electrochem. Solid-State Lett. 2009, 12, A61.

|

| [13] |

Pan H.L.; Shao Y.Y.; Yan P.F.; Cheng Y.W.; Han K.S.; Nie Z.M.; Wang C.M.; Yang J.H.; Li X.L.; Bhattacharya P.; Mueller K.T.; Liu J. Nat. Energy 2016, 1, 16039.

|

| [14] |

Wang J.; Wang J.G.; Liu H.; Wei C.; Kang F. J. Mater. Chem. 2019, 7, 13727.

|

| [15] |

Alfaruqi M.H.; Mathew V.; Song J.J.; Kim S.; Islam S.; Pham D.T.; Jo J.; Kim S.; Baboo J.P.; Xiu Z.L.; Lee K.S.; Sun Y.K.; Kim J. Chem. Mater. 2017, 29, 1684.

|

| [16] |

He P.; Yan M.Y.; Zhang G.B.; Sun R.M.; Chen L.N.; An Q.Y.; Mai L.Q. Adv. Energy Mater. 2017, 7, 1601920.

|

| [17] |

Zeng Y.X.; Zhang X.Y.; Meng Y.; Yu M.H.; Yi J.N.; Wu Y.Q.; Lu X.H.; Tong Y.X. Adv. Mater. 2017, 29, 1700274.

|

| [18] |

Qiu W.D.; Li Y.; You A.; Zhang Z.M.; Li F.G.; Lu X.H.; Tong Y.X. J. Mater. Chem. 2017, 5, 28.

|

| [19] |

Alfaruqi M.H.; Gim J.; Kim S.J.; Song J.J.; Jo J.; Kim S.; Mathew V.; Kim J. J. Power Sources 2015, 288, 320.

|

| [20] |

Alfaruqi M.H.; Mathew V.; Gim J.; Kim S.; Song J.J.; Baboo J.P.; Choi S.H.; Kim J. Chem. Mater. 2015, 27, 3609.

|

| [21] |

Alfaruqi M.H.; Gim J.; Kim S.; Song J.J.; Pham D.T.; Jo J.; Xiu Z.L.; Mathew V.; Kim J. Electrochem. Commun. 2015, 60, 121.

|

| [22] |

Fu Y.Q.; Wei Q.L.; Zhang G.X.; Wang X.M.; Zhang J.H.; Hu Y.F.; Wang D.N.; Zuin L.; Zhou T.; Wu Y.C.; Sun S.H. Adv. Energy Mater. 2018, 8, 1801445.

|

| [23] |

Deng Z.H.; Huang J.D.; Liu J.; Ren L.; Zhu L.Z.; Xiao X.Y.; Tan M.X. Mater. Lett. 2019, 248, 207.

|

| [24] |

Yan T.T.; Xing G.L.; Ben T. Acta Chim. Sinica 2018, 76, 366. (in Chinese)

|

|

闫婷婷, 邢国龙, 贲腾, 化学学报, 2018, 76, 366.

|

|

| [25] |

Tong Z.K.; Fang S.; Zheng H.; Zhang X.G. Acta Chim. Sinica 2016, 74, 185. (in Chinese)

|

|

童震坤, 方姗, 郑浩, 张校刚, 化学学报, 2016, 74, 185.

|

|

| [26] |

Yang B.B.; Wang J.; Bin D.; Zhu M.S.; Yang P.; Du Y.K. J. Mater. Chem. 2015, B3, 7440.

|

| [27] |

Huang Y.; Liu H.; Gong L.; Hou Y.L.; Li Q. J. Power Sources 2017, 347, 29.

|

| [28] |

Wang D.H.; Li H.F.; Liu Z.X.; Tang Z.J.; Liang G.J.; Mo F.N.; Yang Q.; Ma L.T.; Zhi C.Y. Small 2018, 14, 1803978.

|

| [29] |

Wang Q.F.; Zou R.Q.; Xia W.; Ma J.; Qiu B.; Mahmood A.; Zhao R.; Yang Y.Y.C.; Xia D.G.; Xu Q. Small 2015, 11, 2511.

|

| [30] |

Guo S.P.; Li J.C.; Ma Z.; Chi Y.; Xue H.G. J. Mater. Sci. 2016, 52, 2345.

|

| [31] |

Toupin M.; Brousse T.; Daniel B. Chem. Mater. 2004, 16, 3184.

|

| [32] |

Wang J.J.; Wang J.G.; Liu H.Y.; Wei C.G.; Kang F.Y. J. Mater. Chem. A 2019, 7, 13727.

|

| [33] |

Fang G.Z.; Zhou J.; Pan A.Q.; Liang S.Q. ACS Energy Lett. 2018, 3, 2480.

|

| [34] |

Zhou J.; Shan L.T.; Tang B.Y.; Liang S.Q. Chin. Sci. Bull. 2020, 65, 3562. (in Chinese)

|

|

周江, 单路通, 唐博雅, 梁叔全, 科学通报, 2020, 65, 3562.

|

|

| [35] |

Huang J.T.; Zhou J.; Liang S.Q. Acta Phys.-Chim. Sinica 2021, 37, 2005020. (in Chinese)

|

|

黄江涛, 周江, 梁叔全, 物理化学学报, 2021, 37, 2005020.

|

|

| [36] |

Huang J.H.; Wang Z.; Hou M.; Dong X.L.; Liu Y.; Wang Y.; Xia Y. Nat. Commun. 2018, 9, 2906.

|

| [37] |

Xu C.J.; Li B.H.; Du H.D.; Kang F.Y. Angew. Chem. Int. Ed. 2012, 51, 933.

|

| [38] |

Zuo S.Y.; Xu X.J.; Ji S.M.; Wang Z.S.; Liu Z.B.; Liu J. Chem. Eur. J. 2020, 26, 1.

|

| [39] |

Wang S.Y.; Wei Q.L.; He P.; Chen Y.; Xu X.; An Q.Y.; Shuang Y.; Shao Y.Y.; Mai L.Q.; Liu J.; Yang J.H. Adv. Mater. 2018, 30, 1703725.

|

| [40] |

Zhang Y.; Deng S.J.; Luo M.; Pan G.X.; Zeng Y.X.; Lu X.H.; Ai C.Z.; Liu Q.; Xiong Q.Q.; Wang X.L.; Xia X.H.; Tu J.P. Small 2019, 15, 1905452.

|

| [41] |

Fen X.M.; Huang X.W.; Tan Z.; Zhao B.; Tan S.T. Acta Chim. Sinica 2011, 69, 653. (in Chinese)

|

|

冯小明, 黄先威, 谭卓, 赵斌, 谭松庭, 化学学报, 2011, 69, 653.

|

|

| [42] |

Li C.P.; Xie X.S.; Liang S.Q.; Zhou J. Energy Environ. Mater. 2020, 3, 146.

|

| [43] |

Liu N.N.; Wu X.; Yin Y.Y.; Chen A.S.; Zhao C.Y.; Guo Z.K.; Fan L.S.; Zhang N.Q. ACS Appl. Mater. Interfaces 2020, 12, 28199.

|

| [1] | 李萍, 杨琪玉, 曾婧, 张然, 陈秋燕, 闫飞. 氟掺杂对可逆固体氧化物电池性能的影响及相关动力学研究[J]. 化学学报, 2024, 82(1): 36-45. |

| [2] | 刘士琨, 邓程维, 姬峰, 闵宇霖, 李和兴. 高温质子交换膜燃料电池中阴极双催化层孔结构的设计研究★[J]. 化学学报, 2023, 81(9): 1135-1141. |

| [3] | 何家伟, 焦柳, 程雪怡, 陈光海, 吴强, 王喜章, 杨立军, 胡征. 金属有机框架衍生的空心碳纳米笼的结构调控与锂硫电池性能研究[J]. 化学学报, 2022, 80(7): 896-902. |

| [4] | 黄擎, 丁瑞, 陈来, 卢赟, 石奇, 张其雨, 聂启军, 苏岳锋, 吴锋. Na2PO3F对LiNi0.83Co0.11Mn0.06O2材料的复合改性及机理分析[J]. 化学学报, 2022, 80(2): 150-158. |

| [5] | 薛晓兰, 张洋, 石美瑜, 李天琳, 黄天龙, 戚继球, 委福祥, 隋艳伟, 金钟. 有机电极材料在非水系金属镁二次电池中的研究进展[J]. 化学学报, 2022, 80(12): 1618-1628. |

| [6] | 邱凯, 严铭霞, 赵守旺, 安胜利, 王玮, 贾桂霄. Al掺杂的锂离子电池层状正极材料Li(Li0.17Ni0.17Al0.04Fe0.13Mn0.49)O2结构稳定性及氧离子氧化的理论研究[J]. 化学学报, 2021, 79(9): 1146-1153. |

| [7] | 李童心, 李东林, 张清波, 高建行, 孔祥泽, 樊小勇, 苟蕾. 大孔高镍LiNi0.8Co0.1Mn0.1O2正极材料的制备及其电化学性能研究[J]. 化学学报, 2021, 79(5): 678-684. |

| [8] | 林碧霞, 黄颖珊, 陈帅, 邢震宇. 钠硒电池关键材料的研究进展[J]. 化学学报, 2021, 79(5): 641-648. |

| [9] | 张璐, 王文凤, 张洪明, 韩树民, 王利民. 水系锌离子电池研究进展和挑战[J]. 化学学报, 2021, 79(2): 158-175. |

| [10] | 梁其梅, 郭昱娇, 郭俊明, 向明武, 刘晓芳, 白玮, 宁平. 亚微米去顶角八面体LiNi0.08Mn1.92O4正极材料制备及高温电化学性能[J]. 化学学报, 2021, 79(12): 1526-1533. |

| [11] | 谢佶晟, 肖竹梅, 左文华, 杨勇. 钠离子电池钴酸钠正极材料研究进展[J]. 化学学报, 2021, 79(10): 1232-1243. |

| [12] | 汤功奥, 毛鲲, 张静, 吕品, 程雪怡, 吴强, 杨立军, 王喜章, 胡征. 分级结构氮掺杂碳纳米笼:高倍率长寿命可充电镁电池正极材料[J]. 化学学报, 2020, 78(5): 444-450. |

| [13] | 刘九鼎, 张宇栋, 刘俊祥, 李金翰, 邱晓光, 程方益. 磷酸锂原位包覆富锂锰基锂离子电池正极材料[J]. 化学学报, 2020, 78(12): 1426-1433. |

| [14] | 任旭强, 李东林, 赵珍珍, 陈光琦, 赵坤, 孔祥泽, 李童心. 铝掺杂及钨酸锂表面包覆双效提升富锂锰基正极材料的循环稳定性[J]. 化学学报, 2020, 78(11): 1268-1274. |

| [15] | 渠璐平, 任彤, 王宁, 史月丽, 庄全超. 硬碳材料电极首周嵌钠过程的电化学阻抗谱研究[J]. 化学学报, 2019, 77(7): 634-640. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||