化学学报 ›› 2023, Vol. 81 ›› Issue (9): 1135-1141.DOI: 10.6023/A23040184 上一篇 下一篇

所属专题: 庆祝《化学学报》创刊90周年合辑

研究论文

刘士琨a, 邓程维b, 姬峰b, 闵宇霖a,*( ), 李和兴a,*(

), 李和兴a,*( )

)

投稿日期:2023-04-29

发布日期:2023-07-13

作者简介:基金资助:

Shikun Liua, Chengwei Dengb, Feng Jib, Yulin Mina( ), Hexing Lia(

), Hexing Lia( )

)

Received:2023-04-29

Published:2023-07-13

Contact:

*E-mail: About author:Supported by:文章分享

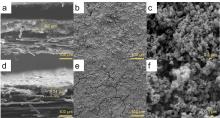

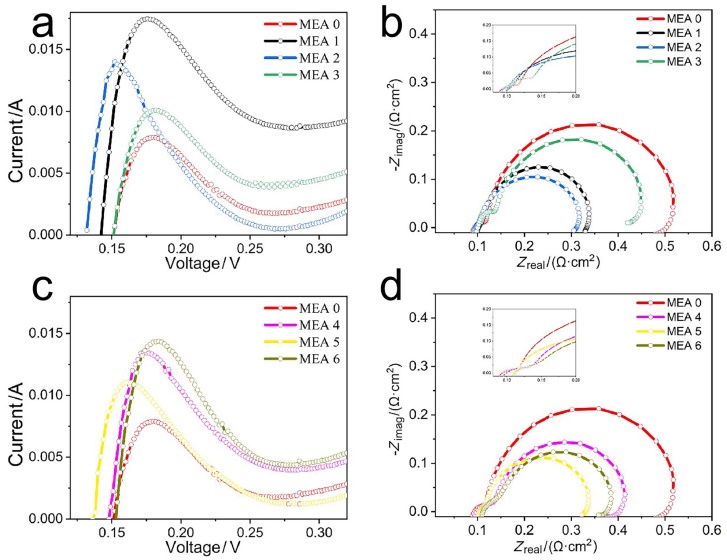

优化气体扩散电极(GDE)的结构是提升高温质子交换膜燃料电池(HT-PEMFC)性能、降低成本的重要手段. 本工作通过调控内外催化层中碳酸氢铵造孔剂含量, 构筑了一种梯度孔分布的双催化层阴极, 优化磷酸分布, 降低氧传输阻力, 从而达到电化学性能提升的目的. 结果显示, 当内催化层使用46.7% (w) PtCo/C且不添加造孔剂, 外催化层使用40% (w) Pt/C且铂与造孔剂质量比为0.53时构成的膜电极, 在160 ℃与常压氢空进料下, 其组成的单电池最大功率密度达439 mW•cm-2, 比未添加造孔剂的单电池最大功率密度高69 mW•cm-2.

刘士琨, 邓程维, 姬峰, 闵宇霖, 李和兴. 高温质子交换膜燃料电池中阴极双催化层孔结构的设计研究★[J]. 化学学报, 2023, 81(9): 1135-1141.

Shikun Liu, Chengwei Deng, Feng Ji, Yulin Min, Hexing Li. Design and Study on Pore Structure of Cathode Double Catalytic Layer in High-temperature Proton Exchange Membrane Fuel Cell★[J]. Acta Chimica Sinica, 2023, 81(9): 1135-1141.

| 内CL | 外CL | ||||

|---|---|---|---|---|---|

| Pt载量/ (mg•cm-2) | 造孔剂质量∶总固体质量/% | Pt载量/ (mg•cm-2) | Pt载量/ (mg•cm-2) | ||

| MEA 0 | 0.250 | 0 | 0.253 | 0.250 | |

| MEA 1 | 0.252 | 0 | 0.248 | 0.252 | |

| MEA 2 | 0.251 | 0 | 0.248 | 0.251 | |

| MEA 3 | 0.250 | 0 | 0.251 | 0.250 | |

| MEA 4 | 0.249 | 10 | 0.253 | 0.249 | |

| MEA 5 | 0.252 | 10 | 0.251 | 0.252 | |

| MEA 6 | 0.250 | 10 | 0.252 | 0.250 | |

| 内CL | 外CL | ||||

|---|---|---|---|---|---|

| Pt载量/ (mg•cm-2) | 造孔剂质量∶总固体质量/% | Pt载量/ (mg•cm-2) | Pt载量/ (mg•cm-2) | ||

| MEA 0 | 0.250 | 0 | 0.253 | 0.250 | |

| MEA 1 | 0.252 | 0 | 0.248 | 0.252 | |

| MEA 2 | 0.251 | 0 | 0.248 | 0.251 | |

| MEA 3 | 0.250 | 0 | 0.251 | 0.250 | |

| MEA 4 | 0.249 | 10 | 0.253 | 0.249 | |

| MEA 5 | 0.252 | 10 | 0.251 | 0.252 | |

| MEA 6 | 0.250 | 10 | 0.252 | 0.250 | |

| 电压/V | 最大功率密度/ (mW•cm-2) | |||||

|---|---|---|---|---|---|---|

| 0.2 A•cm-2 | 0.5 A•cm-2 | 1.2 A•cm-2 | ||||

| MEA 0 | 0.618 | 0.507 | 0.306 | 370 | ||

| MEA 1 | 0.615 | 0.518 | 0.352 | 425 | ||

| MEA 2 | 0.632 | 0.531 | 0.366 | 439 | ||

| MEA 3 | 0.605 | 0.500 | 0.301 | 363 | ||

| MEA 4 | 0.619 | 0.514 | 0.316 | 379 | ||

| MEA 5 | 0.606 | 0.523 | 0.359 | 432 | ||

| MEA 6 | 0.620 | 0.521 | 0.342 | 410 | ||

| 电压/V | 最大功率密度/ (mW•cm-2) | |||||

|---|---|---|---|---|---|---|

| 0.2 A•cm-2 | 0.5 A•cm-2 | 1.2 A•cm-2 | ||||

| MEA 0 | 0.618 | 0.507 | 0.306 | 370 | ||

| MEA 1 | 0.615 | 0.518 | 0.352 | 425 | ||

| MEA 2 | 0.632 | 0.531 | 0.366 | 439 | ||

| MEA 3 | 0.605 | 0.500 | 0.301 | 363 | ||

| MEA 4 | 0.619 | 0.514 | 0.316 | 379 | ||

| MEA 5 | 0.606 | 0.523 | 0.359 | 432 | ||

| MEA 6 | 0.620 | 0.521 | 0.342 | 410 | ||

| RΩ/(mΩ•cm2) | Rp/(mΩ•cm2) | (Rct+Rmt)/(mΩ•cm2) | |

|---|---|---|---|

| MEA 0 | 0.091 | 0.038 | 0.388 |

| MEA 1 | 0.094 | 0.018 | 0.24 |

| MEA 2 | 0.099 | 0.021 | 0.204 |

| MEA 3 | 0.112 | 0.043 | 0.303 |

| MEA 4 | 0.108 | 0.049 | 0.264 |

| MEA 5 | 0.112 | 0.025 | 0.214 |

| MEA 6 | 0.118 | 0.046 | 0.221 |

| RΩ/(mΩ•cm2) | Rp/(mΩ•cm2) | (Rct+Rmt)/(mΩ•cm2) | |

|---|---|---|---|

| MEA 0 | 0.091 | 0.038 | 0.388 |

| MEA 1 | 0.094 | 0.018 | 0.24 |

| MEA 2 | 0.099 | 0.021 | 0.204 |

| MEA 3 | 0.112 | 0.043 | 0.303 |

| MEA 4 | 0.108 | 0.049 | 0.264 |

| MEA 5 | 0.112 | 0.025 | 0.214 |

| MEA 6 | 0.118 | 0.046 | 0.221 |

| [1] |

Xiao, F.; Wang, Y.; Wu, Z.; Chen, G.; Yang, F.; Zhu, S.; Shao, M. Adv. Mater. 2021, 33, 2006292.

doi: 10.1002/adma.v33.50 |

| [2] |

Tang, M. H.; Zhang, S. M.; Chen, S. L. Chem. Soc. Rev. 2022, 51, 1529.

doi: 10.1039/D1CS00981H |

| [3] |

Chen, J. N.; Bailey, J. J.; Britnell, L.; Maria, P. P.; Zhang, Z.; Strudwick, A.; Hack, J.; Guo, Z. M.; Martin, P.; Dan, J. L.; Stuart, M. H. Nano Energy 2022, 93, 106829.

doi: 10.1016/j.nanoen.2021.106829 |

| [4] |

Hong, L. H.; Wang, B. L.; Zhao, C. G. Appl. Surf. Sci. 2019, 31, 785.

|

| [5] |

Mazúr, P.; Soukup, J.; Paidar, M.; Bouzek, K. J. Appl. Electrochem. 2011, 41, 1013.

doi: 10.1007/s10800-011-0325-9 |

| [6] |

Yurko, Y.; Elbaz, L. Electrochim. Acta 2021, 389, 138676.

doi: 10.1016/j.electacta.2021.138676 |

| [7] |

Tian, X. L.; Xu, Y. Y.; Zhang, W. Y.; Wu, T.; Xia, B. Y.; Wang, X. ACS Energy Lett. 2017, 2, 2035.

doi: 10.1021/acsenergylett.7b00593 |

| [8] |

Wannek, C.; Lehnert, W.; Mergel, J. J. Power Sources 2009, 192, 258.

doi: 10.1016/j.jpowsour.2009.03.051 |

| [9] |

Yin, Y.; Liu, J.; Chang, Y. F.; Zhu, Y. Z.; Xie, X.; Qin, Y. Z.; Zhang, J. F.; Jiao, K.; Guiver, M. D. Electrochim. Acta 2018, 296, 450.

doi: 10.1016/j.electacta.2018.11.048 |

| [10] |

Ji, Z. Q.; Chen, J. N.; Guo, Z. M.; Zhao, Z. Y.; Cai, R. S.; Rigby, T. P.; Sarah, J.; Shen, Y. T.; Holmes, S. M. J. Energy Chem. 2022, 75, 399.

doi: 10.1016/j.jechem.2022.08.004 |

| [11] |

Li, W. W.; Shang, Y. M.; Wang, S. B.; Xie, X. F.; Lu, Y. F. Chem. Eng. J. 2011, 62, 131. (in Chinese)

|

|

(李微微, 尚玉明, 王树博, 谢晓峰, 吕亚非, 化工学报, 2011, 62, 131.)

|

|

| [12] |

Lee, E.; Kim, D. H.; Pak, C. H. Appl. Surf. Sci. 2020, 510, 145461.

doi: 10.1016/j.apsusc.2020.145461 |

| [13] |

Kazeminasab, B.; Rowshanzamir, S.; Ghadamian, H. Korean J. Chem. Eng. 2017, 34, 2978.

doi: 10.1007/s11814-017-0202-2 |

| [14] |

Barron, O.; Su, H. N.; Linkov, V.; Pollet, B. G.; Pasupathi, S. K. J. Power Sources 2015, 278, 718.

doi: 10.1016/j.jpowsour.2014.12.139 |

| [15] |

Gao, C. M.; Hu, M. S.; Wang, L.; Wang, L. Polymers 2020, 12, 515.

doi: 10.3390/polym12030515 |

| [16] |

Sun, M.; Huang, J. C.; Xia, Z. G.; Wang, S. L.; Sun, G. G. AIChE J. 2022, 68, 8.

|

| [17] |

Kim, S.; Yuk, S.; Kim, H. G.; Choi, C. Y.; Kim, R. Y.; Lee, J. Y.; Hong, Y. T.; Kim, H. T. J. Mater. 2017, 5, 33.

|

| [18] |

Seland, F.; Berning, T.; Børresen, B.; Tunold, R. J. Power Sources 2006, 160, 1.

doi: 10.1016/j.jpowsour.2005.12.081 |

| [19] |

Kim, G. H.; Eom, S.; Kim, M. J.; Yoo, S. J.; Jang, J. H.; Kim, H.; Cho, E. ACS Appl. Mater. Interfaces 2015, 7, 27581.

doi: 10.1021/acsami.5b07346 |

| [20] |

Su, H. N.; Liang, H. G.; Bladergroen, J.; Linkov, V.; Pollet, B. G.; Pasupathi, S. J. Electrochem. 2014, 161, 4.

|

| [21] |

Liu, S.; Klaus, W.; Werner, L. Int. J. Hydrog. 2021, 46, 27.

|

| [22] |

Zhang, J. J.; Wang, H. N.; Li, W.; Zhang, J.; Lu, D.; Yan, W.; Xiang, Y.; Lu, S. F. J. Power Sources 2021, 505, 230059.

doi: 10.1016/j.jpowsour.2021.230059 |

| [23] |

Bender, G.; Zawodzinski, T.; Saab, A. P. J. Power Sources 2003, 124, 114.

doi: 10.1016/S0378-7753(03)00735-3 |

| [24] |

Chung, Y. H.; Kim, S. J.; Chung, D. Y.; Park, H. Y.; Sung, Y. E.; Yoo, S.; Jang, J. ChemComm. 2015, 51, 2968.

|

| [25] |

Chao, G.; Tang, H. Y.; Ju, Q.; Li, N. W.; Geng, K. J. Power Sources 2023, 556, 232473.

doi: 10.1016/j.jpowsour.2022.232473 |

| [26] |

Yoon, Y. G.; Yang, T. H.; Park, G. G.; Lee, W. Y.; Kim, C. S. J. Power Sources 2003, 118, 189.

doi: 10.1016/S0378-7753(03)00092-2 |

| [27] |

Su, H. N.; Jao, T. C.; Pasupathi, S.; Bladergroen, B. J.; Linkov, V.; Pollet, B. G. J. Power Sources 2014, 246, 63.

doi: 10.1016/j.jpowsour.2013.07.062 |

| [28] |

Garsany, Y.; Atkinson, R. W.; Gould, R. D.; Martin, R.; Dubau, L.; Chatenet, M.; Swider, K. M. J. Power Sources 2021, 514, 230514.

|

| [29] |

Zlotorowicz, A.; Jayasayee, K.; Dahl, P. I.; Thomassen, M. S.; Kjelstrup, S. J. Power Sources 2015, 287, 472.

doi: 10.1016/j.jpowsour.2015.04.079 |

| [30] |

Zhao, J.; He, X.; Wang, L.; Tian, J.; Wan, C.; Jiang, C. Int. J. Hydrog. 2007, 32, 380.

doi: 10.1016/j.ijhydene.2006.06.057 |

| [31] |

Tian, J. H.; Liu, B. W.; Liu, X.; Zhu, K.; Chen, Y. X. PST. 2005, 03, 154. (in Chinese)

|

|

(田建华, 刘邦卫, 刘翔, 朱科, 陈延禧, 化学电源, 2005, 03, 154.)

|

|

| [32] |

Gloaguen, F.; Convert, P.; Gamburzev, S.; Velev, O. A.; Srinivasan, S. Electrochim. Acta 1998, 43, 3767.

doi: 10.1016/S0013-4686(98)00136-4 |

| [33] |

Cui, L. R.; Zhang, J.; Sun, Y. Y.; Lu, S. F.; Xiang, Y. Acta Chim. Sinica 2019, 77, 47. (in Chinese)

doi: 10.6023/A18080344 |

|

(崔丽瑞, 张劲, 孙一焱, 卢善富, 相艳, 化学学报, 2019, 77, 47.)

doi: 10.6023/A18080344 |

|

| [34] |

Wang, M.; Chen, M.; Yang, Z. Y.; Liu, G. C.; Lee, J. K.; Yang, W.; Wang, X. D. Energy Convers. Manag. 2019, 191, 132.

doi: 10.1016/j.enconman.2019.04.014 |

| [35] |

Ji, F.; Zheng, B. W.; Luo, R. Y.; Du, W.; Deng, C. W.; Yang, S.; Liu, Z. Q. Chem. Ind. Eng. Prog. 2022, 41, 5325. (in Chinese)

|

|

(姬峰, 郑博文, 罗若尹, 杜玮, 邓呈维, 杨声, 刘志强, 化工进展, 2022, 41, 5325.)

doi: 10.16085/j.issn.1000-6613.2021-2558 |

|

| [36] |

Bevilacqua, N.; Schmid, M.; Zeis, R. Power Sources. 2020, 471, 228469.

doi: 10.1016/j.jpowsour.2020.228469 |

| [37] |

Zhang, W. Q.; Yao, D. G.; Tian, L. L.; Xie, Z.; Ma, Q.; Xu, Q.; Pasupathi, S.; Xing, L.; Su, H. N. J. Taiwan Inst. Chem. Eng. 2021, 125, 258.

|

| [38] |

Wang, H. S.; Chih, P. H.; Shiuan, W. S.; Tseng, Y. J.; Gang, F. J. Am. Chem. Soc. 2012, 243, 529.

|

| [39] |

Zhang, S. M. Ph.D. Dissertation, Zhejiang University, Hangzhou, 2023. (in Chinese)

|

|

(张硕猛, 博士论文, 浙江大学, 杭州, 2023.)

|

|

| [40] |

Duan, K. J.; Roswitha, Z.; Sui, B. J. J. Chongqing Univ. 2022, 45, 34. (in Chinese)

|

|

(段康俊, Roswitha, Z., 隋邦傑, 重庆大学学报, 2022, 45, 34.)

|

|

| [41] |

Bjorn, W. J.; Douglas, R. M. Energy Environ. Sci. 2011, 4, 2790.

doi: 10.1039/c0ee00652a |

| [42] |

Li, T. Y.; Wang, K. J.; Wang, J. H.; Liu, Y. Q.; Han, Y. F.; Song, J. H.; Hu, H. W.; Lin, G. G.; Liu, Y. Mater. Sci. 2020, 55, 4558.

doi: 10.1007/s10853-019-04323-9 |

| [43] |

Eunae, L.; Do-Hyung, K.; Chanho, P. Appl. Surf. Sci. 2020, 510, 13242.

|

| [1] | 李萍, 杨琪玉, 曾婧, 张然, 陈秋燕, 闫飞. 氟掺杂对可逆固体氧化物电池性能的影响及相关动力学研究[J]. 化学学报, 2024, 82(1): 36-45. |

| [2] | 李燕丽, 于丹丹, 林森, 孙东飞, 雷自强. α-MnO2纳米棒/多孔碳正极材料的制备及水系锌离子电池性能研究[J]. 化学学报, 2021, 79(2): 200-207. |

| [3] | 梁其梅, 郭昱娇, 郭俊明, 向明武, 刘晓芳, 白玮, 宁平. 亚微米去顶角八面体LiNi0.08Mn1.92O4正极材料制备及高温电化学性能[J]. 化学学报, 2021, 79(12): 1526-1533. |

| [4] | 渠璐平, 任彤, 王宁, 史月丽, 庄全超. 硬碳材料电极首周嵌钠过程的电化学阻抗谱研究[J]. 化学学报, 2019, 77(7): 634-640. |

| [5] | 宋学霞, 李继成, 李朝晖, 李喜飞, 丁燕怀, 肖启振, 雷钢铁. 钾掺杂对钒酸钠纳米片储钠性能的影响[J]. 化学学报, 2019, 77(7): 625-633. |

| [6] | 常世磊, 梁风, 姚耀春, 马文会, 杨斌, 戴永年. 金属二氧化碳电池的研究进展[J]. 化学学报, 2018, 76(7): 515-525. |

| [7] | 郑媛, 罗静, 魏玮, 刘晓亚. Pickering乳液法制备聚苯胺-石墨烯空心微球[J]. 化学学报, 2017, 75(4): 391-397. |

| [8] | 刘清朝, 马诗喻, 徐吉静, 李中军, 张新波. 锂-空气二次电池关键材料与器件的设计与制备[J]. 化学学报, 2017, 75(2): 137-146. |

| [9] | 杨春, 龚正良, 赵文高, 杨勇. 富锂正极材料xLi3NbO4·(1-x)LiMO2(M=Mn,Co;0 < x < 1)的制备及电化学性能研究[J]. 化学学报, 2017, 75(2): 212-217. |

| [10] | 孔丽娟, 周晓燕, 范赛英, 李在均, 顾志国. 组氨酸功能化石墨烯量子点@纳米硅负极材料的制备及电化学性能研究[J]. 化学学报, 2016, 74(7): 620-628. |

| [11] | 刘欣, 解晶莹, 赵海雷, 王可, 汤卫平, 潘延林, 丰震河, 吕鹏鹏. 锂离子电池Sn30Co30C40三元合金负极材料的制备与性能研究[J]. 化学学报, 2013, 71(07): 1011-1016. |

| [12] | 马利, 梁卫朝, 甘孟瑜, 黄超群, 谷静连, 杨雅文, 李王林, 张峰. APS/NaClO 复合氧化剂对乳液法合成聚苯胺的微观形貌及其电化学性能的影响[J]. 化学学报, 2012, 70(10): 1207-1212. |

| [13] | 左晓希, 李奇, 刘建生, 肖信, 范成杰, 南俊民. LiPF6/三氟乙酰胺室温熔盐的制备及在碳-碳电容器中的性能[J]. 化学学报, 2012, 70(04): 367-371. |

| [14] | 马利, 谷静连, 甘孟瑜, 梁卫朝, 黄超群, 杨雅文, 张峰, 李王林. 砂磨法制备聚苯胺及其电化学性能的研究[J]. 化学学报, 2011, 69(24): 3007-3012. |

| [15] | 夏笑虹, 石磊, 何月德, 杨丽, 刘洪波. 炭化温度对烟杆基活性炭孔结构及电化学性能的影响研究[J]. 化学学报, 2011, 69(21): 2627-2631. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||