化学学报 ›› 2024, Vol. 82 ›› Issue (6): 596-603.DOI: 10.6023/A24030079 上一篇 下一篇

研究论文

付祎帅, 王文亮*( ), 苗晖, 陈育彤, 崔洋怡, 王紫薇, 潘佳文, 肖国伟

), 苗晖, 陈育彤, 崔洋怡, 王紫薇, 潘佳文, 肖国伟

投稿日期:2024-03-11

发布日期:2024-05-12

基金资助:

Yishuai Fu, Wenliang Wang*( ), Hui Miao, Yutong Chen, Yangyi Cui, Ziwei Wang, Jiawen Pan, Guowei Xiao

), Hui Miao, Yutong Chen, Yangyi Cui, Ziwei Wang, Jiawen Pan, Guowei Xiao

Received:2024-03-11

Published:2024-05-12

Contact:

* E-mail: Supported by:文章分享

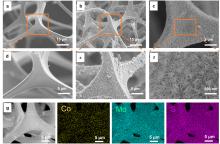

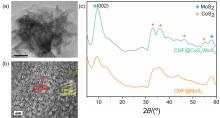

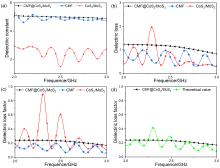

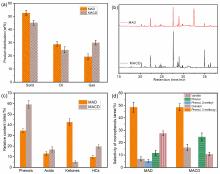

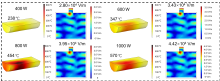

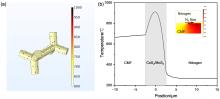

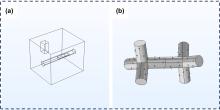

本研究以Anderson型多金属氧酸盐 (NH4)3[CoMo6O24H6]•6H2O为前驱体, 采用一步水热法制备微波响应型CMF@CoS2/MoS2催化剂. 当微波频率为2.45 GHz时, 催化剂拥有良好的微波吸收性能(介电损耗正切角值0.23), 证明了其拥有优异的微波响应能力. 木质素蒸气微波辅助催化解聚(MACD)实验表明, CMF@CoS2/MoS2显著提高了单酚产率(59.30%)和苯酚选择性(24.69%). 多物理场耦合分析表明, CMF@CoS2/MoS2由于其优异的微波吸收性, 能够通过“热点效应”增强局部反应温度, 使木质素蒸气(570 ℃)吸附于高温CoS2/MoS2活性组分(910 ℃)表面进一步促进其催化重整. 本工作开发的新型微波响应型CMF@CoS2/MoS2催化剂为从木质素炼制高价值酚类平台化合物提供了新的途径.

付祎帅, 王文亮, 苗晖, 陈育彤, 崔洋怡, 王紫薇, 潘佳文, 肖国伟. 微波响应型CMF@CoS2/MoS2催化剂的制备及其用于木质素蒸气的催化重整[J]. 化学学报, 2024, 82(6): 596-603.

Yishuai Fu, Wenliang Wang, Hui Miao, Yutong Chen, Yangyi Cui, Ziwei Wang, Jiawen Pan, Guowei Xiao. Fabrication of Microwave-responsive CMF@CoS2/MoS2 Catalyst and Highly Efficient Reforming of Lignin Vapor by Microwave Irradiation[J]. Acta Chimica Sinica, 2024, 82(6): 596-603.

| 参数名称 | 参数值 |

|---|---|

| 相对磁导率μr | 1 |

| 相对介电常数(CMF@CoS2/MoS2) εr | 5.00-1.17*j |

| 相对介电常数(CoS2/MoS2) εr | 2.39-0.73*j |

| 相对介电常数(CMF) εr | 5.01-0.98*j |

| 相对介电常数(木质素(脱碱)) εr | 3.08-0.13*j |

| 电导率σ/(S•m-1) | 0 |

| 比热率 | 1.24 |

| 密度/(kg•m-3) | 12 |

| 参数名称 | 参数值 |

|---|---|

| 相对磁导率μr | 1 |

| 相对介电常数(CMF@CoS2/MoS2) εr | 5.00-1.17*j |

| 相对介电常数(CoS2/MoS2) εr | 2.39-0.73*j |

| 相对介电常数(CMF) εr | 5.01-0.98*j |

| 相对介电常数(木质素(脱碱)) εr | 3.08-0.13*j |

| 电导率σ/(S•m-1) | 0 |

| 比热率 | 1.24 |

| 密度/(kg•m-3) | 12 |

| [1] |

Mo, B. C.; Chen, C. X.; Peng, J. S. Chin. J. Org. Chem. 2023, 43, 1215. (in Chinese)

|

|

(莫百川, 陈春霞, 彭进松, 有机化学, 2023, 43, 1215.)

doi: 10.6023/cjoc202207013 |

|

| [2] |

Wong, S. S.; Shu, R. Y.; Zhang, J. G.; Liu, H. C.; Yan, N. Chem. Soc. Rev. 2020, 49, 5510.

|

| [3] |

Mondal, S.; Jatrana, A.; Maan, S.; Sharma, P. Environ. Chem. Lett. 2023, 21, 2171.

|

| [4] |

Bourbiaux, D.; Pu, J. J.; Rataboul, F.; Djakovitch, L.; Geantet, C.; Laurenti, D. Catal. Today 2021, 373, 24.

|

| [5] |

Wang, W. L.; Ma, Z. H.; Ma, Y. J.; Huang, J. L.; Fu, Y. S.; Miao, H.; Wu, J. C.; Dai, S. B. J. Shaanxi Univ. Sci. Technol. 2021, 39, 1. (in Chinese)

|

|

(王文亮, 马振浩, 马玉军, 黄佳乐, 付祎帅, 苗晖, 吴佳聪, 代松伯, 陕西科技大学学报, 2021, 39, 1.)

|

|

| [6] |

Liu, X. X.; Yan, L.; Fu, Y. Acta Chim. Sinica 2017, 75, 788. (in Chinese)

|

|

(刘新鑫, 严龙, 傅尧, 化学学报, 2017, 75, 788.)

doi: 10.6023/A17050199 |

|

| [7] |

Wang, W. L.; Shi, Y. J.; Dang, Z. P.; Tang, N.; Huang, J. L.; Wang, S. H. J. Shaanxi Univ. Sci. Technol. 2018, 36, 1. (in Chinese)

|

|

(王文亮, 时宇杰, 党泽攀, 唐宁, 黄佳乐, 王少华, 陕西科技大学学报, 2018, 36, 1.)

|

|

| [8] |

Shao, L. P.; Zhang, Q. L.; You, T. T.; Zhang, X. M.; Xu, F. Bioresour. Technol. 2018, 264, 238.

|

| [9] |

Zhou, N.; Yang, J.; Lu, X.; Xin, Z.; Xu, C. B.; He, Q. J. Anal. Appl. Pyrolysis 2022, 161, 105403.

|

| [10] |

Yang, J.; Shang, H.; Li, J.; Liao, Y. F.; Yang, C. Z. Mod. Chem. Ind. 2023, 43, 80. (in Chinese)

|

|

(杨捷, 商辉, 李军, 廖逸飞, 杨昌泽, 现代化工, 2023, 43, 80.)

|

|

| [11] |

Ma, Y. J.; Wang, W. L.; Han, S. Z.; Fu, Y. S.; Chen, Y. T.; Huang, J. L.; Quan, J. W.; Zhang, J. Y. J. Shaanxi Univ. Sci. Technol. 2023, 41, 8. (in Chinese)

|

|

(马玉军, 王文亮, 韩思哲, 付祎帅, 陈育彤, 黄佳乐, 权靖雯, 张嘉怡, 陕西科技大学学报, 2023, 41, 8.)

|

|

| [12] |

Wang, W. L.; Wang, M.; Huang, J. L.; Li, X. P.; Cai, L. P.; Shi, S. Q.; Cui, Y.; Chen, L.; Ni, Y. H. J. Cleaner Prod. 2020, 257, 120596.

|

| [13] |

Zhang, J.; Shen, Y.; Zhu, L. Y.; Liu, H. R.; Zhou, Z. Y. Energy Environ. Prot. 2024, 38, 190. (in Chinese)

|

|

(张婧, 沈洋, 诸麟榆, 刘浩然, 周忠岳, 能源环境保护, 2024, 38, 190.)

|

|

| [14] |

Zhang, H. D.; Lan, X. Y.; Cheng, P. Acta Chim. Sinica 2023, 81, 100. (in Chinese)

|

|

(张红丹, 兰欣雨, 程鹏, 化学学报, 2023, 81, 100.)

doi: 10.6023/A22100420 |

|

| [15] |

Wang, W. L.; Ma, Z. H.; Zhao, X. J.; Liu, S. W.; Cai, L. P.; Shi, S. Q.; Ni, Y. H. ACS Sustainable Chem. Eng. 2020, 8, 16086.

|

| [16] |

Zhou, X. W.; Zhou, J.; Yu, Y. W.; Ma, J. Q.; Sun, X. N.; Hu, L. M. Nano 2017, 12, 38.

|

| [17] |

Ji, N.; Diao, X. Y.; Li, X. X.; Jia, Z. C.; Zhao, Y. J.; Lu, X. B.; Song, C. F.; Liu, Q. L.; Li, C. Z. Ind. Eng. Chem. Res. 2020, 59, 17287.

|

| [18] |

Diao, X. Y.; Ji, N. J. Energy Chem. 2023, 77, 601.

|

| [19] |

Liu, X. L.; Hou, X. L.; Zhang, Y. J.; Yuan, H.; Hong, X. L.; Liu, G. L. Ind. Eng. Chem. Res. 2020, 59, 15921.

|

| [20] |

Zavala, L. A.; Kumar, K.; Martin, V.; Maillard, F.; Mauge, F.; Portier, X.; Oliviero, L.; Dubau, L. ACS Catal. 2023, 13, 1221.

|

| [21] |

Yan, J.; Huang, Y.; Chen, C.; Liu, X. G.; Liu, H. Carbon 2019, 152, 545.

|

| [22] |

Wang, X.; Zhang, Y. W.; Si, H. N.; Zhang, Q. H.; Wu, J.; Gao, L.; Wei, X. F.; Sun, Y.; Liao, Q. L.; Zhang, Z.; Ammarah, K.; Gu, L.; Kang, Z.; Zhang, Y. J. Am. Chem. Soc. 2020, 142, 4298.

doi: 10.1021/jacs.9b12113 pmid: 31999446 |

| [23] |

Zhao, Y. P.; Zuo, X. Q.; Guo, Y.; Huang, H.; Zhang, H.; Wang, T.; Wen, N. X.; Chen, H.; Cong, T. Z.; Muhammad, J.; Yang, X.; Wang, X. N.; Fan, Z.; Pan, L. J. Nano-Micro Lett. 2021, 13.

|

| [24] |

Wang, W. l.; Huang, J. L.; Fu, Y. S.; Jiang, W. K.; Chen, Y. T.; Ma, Y. J.; Han, S. Z. Appl. Catal. B-Environ. 2023, 333, 122787.

|

| [25] |

Wang, W. L.; Wang, X. B.; Ma, Z. H.; Duan, C.; Liu, S. W.; Yu, H. L.; Li, X. P.; Cai, L. P.; Shi, S. Q.; Ni, Y. H. FUEL 2021, 285, 119211.

|

| [26] |

Jiang, S. N.; Ji, N.; Diao, X. Y.; Li, H. Y.; Rong, Y.; Lei, Y. X.; Yu, Z. H. ChemSusChem 2021, 14, 4377.

|

| [27] |

Xue, S.; Luo, Z. Y.; Zhou, Q. G.; Sun, H. R.; Du, L. W. Bioresour. Technol. 2021, 337, 125396.

|

| [28] |

Xue, X. F.; Zhang, C. S.; Xia, D.; Wang, Y. G.; Liang, J.; Sun, Y. F. Chem. Eng. J. 2022, 431, 134251.

|

| [29] |

Kloekhorst, A.; Shen, Y.; Yie, Y.; Fang, M.; Heeres, H. J. Biomass Bioenerg. 2015, 80, 147.

|

| [30] |

Jie, X. Y.; Li, W. S.; Slocombe, D.; Gao, Y. G.; Banerjee, I.; Gonzalez-Cortes, S.; Yao, B. Z.; AlMegren, H.; Alshihri, S.; Dilworth, J.; Thomas, J.; Xiao, T.; Edwards, P. Nat. Catal. 2020, 3, 902.

|

| [31] |

Zhu, J. Y.; Yi, L. P.; Yang, Z. Z.; Li, X. G. Fuel 2021, 287, 119553.

|

| [32] |

Yang, H. M.; Han, T.; Shi, Z.; Sun, Y. J.; Jiang, J. C.; Sandstrom, L.; Jonsson, P. G.; Yang, W. H. Fuel Process. Technol. 2022, 227, 107103.

|

| [33] |

Zhang, S. P.; Wang, J. X.; Ye, L.; Li, S.; Su, Y. H.; Zhang, H. Y. Chem. Eng. J. 2023, 454, 140072.

|

| [1] | 刘浩, 徐旭莉, 郭勇, 刘晓晖, 王艳芹. Ru/NiPOx高效电催化醛还原胺化反应的研究[J]. 化学学报, 2024, 82(5): 477-485. |

| [2] | 王国景, 陈永辉, 张秀芹, 张俊笙, 徐俊敏, 王静. 氧空位控制BiVO4晶面异质结的磁性和光电催化性能[J]. 化学学报, 2024, 82(4): 409-415. |

| [3] | 张强, 王欢, 王帅, 王园园, 张梅, 宋华. NiCe(x)/FLRC-TiO2催化剂的制备及其加氢脱氧性能研究[J]. 化学学报, 2024, 82(3): 287-294. |

| [4] | 韩晶, 廖润华, 邓文强, 梁博宇, 周雨晴, 任帅, 洪燕. 铜掺杂氮化碳电催化硝酸盐产氨性能研究[J]. 化学学报, 2024, 82(3): 295-302. |

| [5] | 李雅宁, 王晓艳, 唐勇. 自由基聚合的立体选择性调控★[J]. 化学学报, 2024, 82(2): 213-225. |

| [6] | 崔国庆, 胡溢玚, 娄颖洁, 周明霞, 李宇明, 王雅君, 姜桂元, 徐春明. CO2加氢制醇类催化剂的设计制备及性能研究进展[J]. 化学学报, 2023, 81(8): 1081-1100. |

| [7] | 付信朴, 王秀玲, 王伟伟, 司锐, 贾春江. 团簇Au/CeO2的制备及其催化CO氧化反应构效关系的研究★[J]. 化学学报, 2023, 81(8): 874-883. |

| [8] | 刘建川, 李翠艳, 刘耀祖, 王钰杰, 方千荣. 高稳定二维联咔唑sp2碳共轭共价有机框架材料用于高效电催化氧还原★[J]. 化学学报, 2023, 81(8): 884-890. |

| [9] | 赵天成, 蒋鸿宇, 张琨, 徐一帆, 康欣悦, 胥鉴宸, 周旭峰, 陈培宁, 彭慧胜. 基于环烷烃/乙醇混合碳源高性能碳纳米管纤维的连续化制备[J]. 化学学报, 2023, 81(6): 565-571. |

| [10] | 王子豪, 陈敏, 陈昶乐. 不对称α-二亚胺镍催化制备聚烯烃弹性体★[J]. 化学学报, 2023, 81(6): 559-564. |

| [11] | 刘露杰, 张建, 王亮, 肖丰收. 生物质基多元醇的多相催化选择性氢解★[J]. 化学学报, 2023, 81(5): 533-547. |

| [12] | 徐斌, 韦秀芝, 孙江敏, 刘建国, 马隆龙. 原位合成氮掺杂石墨烯负载钯纳米颗粒用于催化香兰素高选择性加氢反应[J]. 化学学报, 2023, 81(3): 239-245. |

| [13] | 刘健, 欧金花, 李泽平, 蒋婧怡, 梁荣涛, 张文杰, 刘开建, 韩瑜. 金属-有机骨架衍生的Co单原子高效催化硝基芳烃氢化还原[J]. 化学学报, 2023, 81(12): 1701-1707. |

| [14] | 刘金晶, 杨娜, 李莉, 魏子栋. 铂活性位空间结构调控氧还原机理的理论研究★[J]. 化学学报, 2023, 81(11): 1478-1485. |

| [15] | 杨贯文, 伍广朋. 模块化双功能有机硼氮和硼磷催化体系的设计及其催化转化★[J]. 化学学报, 2023, 81(11): 1551-1565. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||