| [1] Hull, C. W. US 04575330, 1986.

[2] Huang, W. D. J. New Industrialization 2016, 6, 53 (in Chinese). (黄卫东, 新型工业化, 2016, 6, 53.)

[3] Gunther, D.; Heymel, B.; Gunther, J. F.; Ederer, I. Rapid Prototyping J. 2014, 20, 320.

[4] Ding, Y. C. Minying Keji 2018, (7), 166(in Chinese). (丁有成, 民营科技, 2018, (7), 166.)

[5] Zhang, M.; Jiang, M.-H.; Wu, G.-H.; Yang, Q.-L. Beverage Ind. 2015, 18, 57(in Chinese). (张明, 姜明洪, 吴光虹, 杨秋玲, 饮料工业, 2015, 18, 57.)

[6] Jing, L. G.; Shen, L. J. Biology Teaching 2016, 41, 6(in Chinese). (井乐刚, 沈丽君, 生物学教学, 2016, 41, 6.)

[7] Hu, Y. P. Mech. Res. Appl. 2016, 29, 193(in Chinese). (胡彦萍, 机械研究与应用, 2016, 29, 193.)

[8] Zhu, G.; Mo, W.-J. Val. Eng. 2015, 34, 178(in Chinese). (朱阁,莫蔚靖, 价值工程, 2015, 34, 178.)

[9] Paulsen, S. J.; Miller, J. S. Dev. Dynam. 2015, 244, 320.

[10] He, C. L.; Tang, Z. H.; Tian, H. Y.; Chen, X. S. Acta Polym. Sin. 2013, (6), 722 (in Chinese). (贺超良, 汤朝晖, 田华雨, 陈学思, 高分子学报, 2013, (6), 722.)

[11] Zhang, X. J.; Tang, S. Y.; Zhao, H. Y.; Guo, S. Q.; Li, N.; Chen, B. Q. J. Mater. Eng. 2016, 44, 122 (in Chinese). (张学军, 唐思熠, 肇恒跃, 郭绍庆, 李能, 孙兵兵, 陈冰清, 材料工程, 2016, 44, 122.)

[12] Chen, S. P.; Yi, H.-P.; Luo, Z. H.; Zhu Ge, X. Q.; Luo, K. Mater. Rev. 2016, 30, 54 (in Chinese). (陈硕平, 易和平, 罗志虹, 诸葛祥群, 罗鲲, 材料导报, 2016, 30, 54.)

[13] Li, X.-L.; Ma, J.-X.; Li, P.; Chen, Q.; Zhou, W.-M. Proc. Autom. Instrum. 2014, 35, 1 (in Chinese). (李小丽, 马剑雄, 李萍, 陈琪, 周伟民, 自动化仪表, 2014, 35, 1.)

[14] Rossi, S.; Puglisi, A.; Benaglia, M. ChemCatChem 2018, 10, 1512.

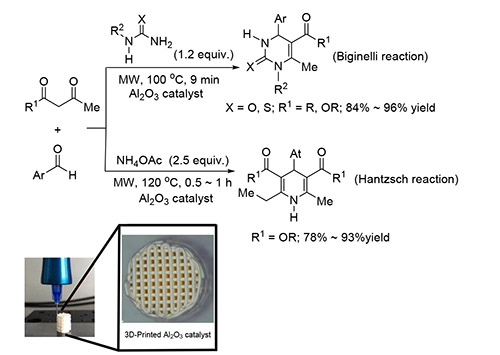

[15] Tubío, C. R.; Azuaje, J.; Escalante, L.; Coelho, A.; Guitián, F.; Sotelo, E.; Gil, A. J. Catal. 2016, 334,110.

[16] Azuaje, J.; Tubío, C. R.; Escalante, L.; Gómez, M.; Guitián, F.; Coelho, A.; Caamaño, O.; Gil, A.; Sotelo, E. Appl. Catal. A-Gen. 2017, 530, 203.

[17] Manzano, J. S.; Weinstein, Z. B.; Sadow, A. D.; Slowing, I. I. ACS Catal. 2017, 7, 7567.

[18] Díaz-Marta, A. S.; Tubío, C. R.; Carbajales, C.; Fernandez, C.; Escalante L.; Sotelo, E.; Guitian, F.; Barrio, V. L.; Gil, A.; Coelho, A. ACS Catal. 2018, 8, 392.

[19] Symes, M. D.; Kitson, P. J.; Yan, J.; Richmond, C. J.; Cooper, G. J.; Bowman, R. W.; Vilbrandt, T.; Cronin, L. Nat. Chem. 2012, 4, 349.

[20] Johnson, R. D. Nat. Chem. 2012, 4, 338.

[21] Kitson, P. J.; Symes, M. D.; Dragone, V.; Cronin, L. Chem. Sci. 2013, 4, 3099.

[22] Kitson, P. J.; Glatzel, S.; Chen, W.; Lin, C. G.; Song, Y. F.; Cronin, L. Nat. Protoc. 2016, 11, 920.

[23] Mathieson, J. S.; Rosnes, M. H.; Sans, V.; Kitson, P. J.; Cronin, L. Beilstein J. Nanotechnol. 2013, 4, 285.

[24] Kitson, P. J.; Glatzel, S.; Cronin, L. Beilstein J. Org. Chem. 2016, 12, 2776.

[25] Zalesskiy, S. S.; Shlapakov, N. S.; Ananikov, V. P. Chem. Sci. 2016, 7, 6740.

[26] Kucherov, F. A.; Gordeev, E. G.; Kashin, A. S.; Ananikov, V. P. Angew. Chem. 2017, 29, 16147.

[27] Gordeev, E. G.; Degtyareva, E. S.; Ananikov, V. P. Russ. Chem. B 2016, 65, 1637.

[28] Lederle, F.; Meyer, F.; Kaldun, C.; Namyslo, J. C.; Hübner, E. G. New J. Chem. 2017, 41, 1925.

[29] Kitson, P. J.; Rosnes, M. H.; Sans, V.; Dragone, V.; Cronin, L. Lab Chip. 2012, 12, 3267.

[30] Dragone, V.; Sans, V.; Rosnes, M. H.; Kitson, P. J.; Cronin, L. Beilstein J. Org. Chem. 2013, 9, 951.

[31] Elias, Y.; von Rohr, P. R.; Bonrath, W.; Medlock, J.; Buss, A. Chem. Eng. Process 2015, 95, 175.

[32] Avril, A.; Hornung, C. H.; Urban, A.; Fraser, D.; Horne, M.; Veder, J. P.; Tsanaktsidis, J.; Rodopoulos, T.; Henry, C.; Gunasegaram, D. R. React. Chem. Eng. 2017, 2, 180.

[33] Hornung, C. H.; Nguyen, X.; Carafa, A.; Gardiner, J.; Urban, A.; Fraser, D.; Horne, M. D.; Gunasegaram, D. R.; Tsanaktsidis, J. Org. Process Res. Dev. 2017, 21, 1311.

[34] Capel, A. J.; Wright, A.; Harding, M. J.; Weaver, G. W.; Li, Y.; Harris, R. A.; Edmondson, S.; Goodridge, R. D.; Christie, S. D. Beilstein J. Org. Chem. 2017, 13, 111.

[35] Rossi, S.; Porta, R.; Brenna, D.; Puglisi, A.; Benaglia, M. Angew. Chem. 2017, 129, 4354.

[36] Rao, Z. X.; Patel, B.; Monaco, A.; Cao, Z. J.; Barniol-Xicota, M.; Pichon, E.; Ladlow, M.; Hilton, S. Eur. J. Org. Chem. 2017, 44, 6499.

[37] Bettermann, S.; Schroeter, B.; Morit, H.-U.; Pauer, W.; Fassbender, W.; Luinstra, G. A. Chem. Eng. J. 2018, 338, 311.

[38] Genet, C.; Nguyen, X.; Bayatsarmadi, B.; Horne, M. D.; Gardiner, J.; Hornung, C. H. J. Flow. Chem. 2018, 8, 81.

[39] Kitson, P. J.; Marie, G.; Francoia, J.-P.; Zalesskiy, S. S.; Sigerson, R. C.; Mathieson, J. S.; Cronin, L. Science 2018, 359, 314.

[40] Huang, J.; Jiang, S. Adv. Mater. Ind. 2013, (1), 62 (in Chinese). (黄健, 姜山, 新材料产业, 2013, (1), 62.) |